While copper is the preferred choice for EV charger installations, other metals like aluminum, stainless steel, and zinc are also used. Ultimately, the choice of conductor will be determined by you and your electrician. While electricians will present all available options, they typically recommend copper due to local codes and regulations, cost-effectiveness, ease of installation, and other specific factors.

Copper is highly recommended for EV charger installations due to its electrical conductivity, corrosion resistance, long life expectancy, low resistance, grounding effectiveness, code compliance, and compatibility with a wide range of electrical accessories used in an electric vehicle branch circuit such as connectors, clamps, conductors, terminals, etc

Copper conductors are often favored for EV charger installations for several key reasons:

Table of Contents

Electrical Conductivity

Copper is a very good conductor of electricity at 5.98×107 (Conductivity σ(S/m) at 20°C), compared to its competitors such as aluminum 3.5×107 (Conductivity σ(S/m) at 20°C), Iron 1.04×107 (Conductivity σ(S/m) at 20°C) and Steel 6.21×106 (Conductivity σ(S/m) at 20°C). This means it allows current to flow easily through it in conductive and inductive charging.

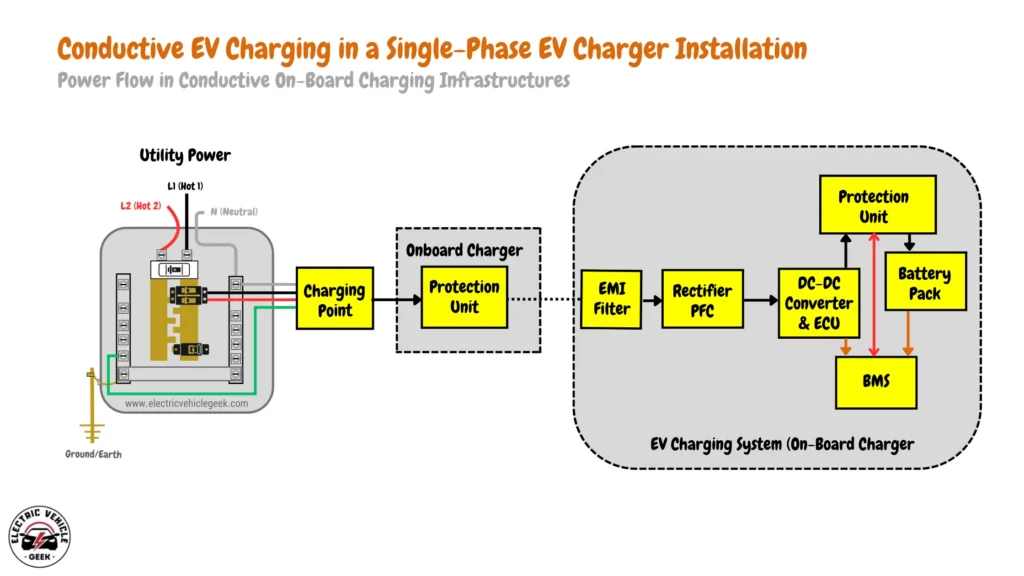

The electrical conductivity of copper is essential in conductive EV charging which involves metal-to-metal contact between the grid and the electric vehicle for charging.

The diagram below shows conductive EV charging in a single-phase EV charger installation:

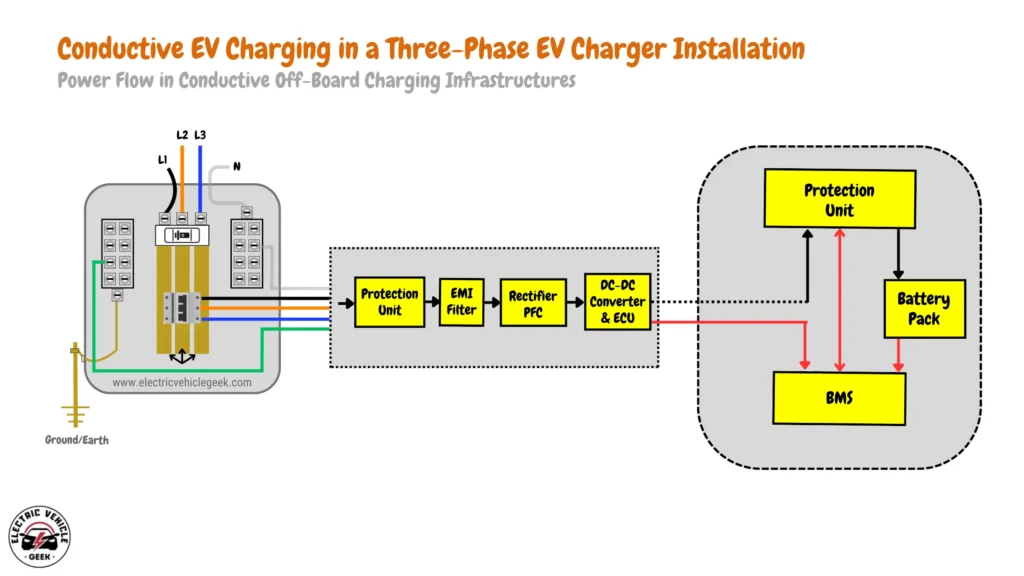

The diagram below shows conductive EV charging in a three-phase EV charger installation:

The use of copper in conductive EV charging makes the EV charger installation highly efficient and robust, ensuring the current is safely and effectively directed to the on-board charging infrastructures and off-board charging infrastructures.

Copper’s ability to handle high, continuous amperage efficiently also makes it the best choice for EV charger earthing and grounding. It ensures that fault currents and leakage currents are safely and promptly directed to the ground, reducing the risk of EV charging fires, EV battery fires, electrical shocks, and damage to the charging infrastructure.

Low Resistance

Copper has a low resistance of 1.68×10-8 (Resistivity p(Ω•m) at 20°C), compared to its competitors such as aluminum 2.82×10-8 (Resistivity p(Ω•m) at 20°C), Iron 9.58×10-8 (Resistivity p(Ω•m) at 20°C) and steel 1.61×10-7 (Resistivity p(Ω•m) at 20°C) making at an efficient conductor for conductive EV charging where metal to metal contact is needed for electrical current to flow through it for EV charging.

The lower resistance of copper conductors allows for smoother current flow from the utility grid to the EV battery, reducing energy loss as heat thanks to its superior thermal conductivity.

Corrosion Resistance

Copper conductors are also highly resistant to corrosion, in EV charger installations they form a protective patina over time, which shields the metal from environmental degradation especially when the conductor is exposed to other elements in indoor and outdoor EV charger installations.

EV charger conductors must maintain reliable electrical conductivity over time, especially for conductive EV charging where efficient metal-to-metal contact is crucial. Copper’s superior corrosion resistance ensures that this essential metal-to-metal contact remains intact, preserving the long-term effectiveness and reliability of the EV charging installation.

Long Life Expectancy

Copper conductors offer a longer lifespan compared to alternatives like aluminum and steel, making them a reliable choice for high-powered EV charger installations. Whether installed indoors or outdoors, EV charger conductors face exposure to moisture, temperature fluctuations, dust, and other environmental factors. Copper’s resistance to metal fatigue from these conditions makes it a more efficient and durable option for EV charger installations.

Compatibility

Copper conductors are highly compatible with a wide range of electrical accessories used in EV charger installations, such as electrical panels, circuit breakers, outlets, connectors, terminals, lugs, and clamps. This compatibility simplifies the installation, maintenance, repair, and replacement of EV charger components when copper conductors are utilized.

Code Compliance

Copper conductors are also used in EV chargers to comply with electrical codes and regulations, for example, the use of copper for EV charger grounding is specified in NEC 250.52(A), 250.53, 250.66, and 250.122. Adhering to local electrical codes in the installation of high powered EV chargers is important to ensure the safety and reliability of your EV charger installations.

James Ndungu is a certified EV charger installer with over five years of experience in EVSE selection, permitting, and installation. He holds advanced credentials, including certification from the Electric Vehicle Infrastructure Training Program (EVITP) and specialized training in EV charging equipment and installation, as well as diplomas in EV Technology and Engineering Fundamentals of EVs. Since 2021, James has tested dozens of EV chargers and accessories, sharing expert insights into the latest EV charging technologies.