An onboard charger (OBC) in an electric vehicle is responsible for converting the Alternating Current (AC) from the power grid into Direct Current (DC) to charge the vehicle’s battery. The OBC regulates the charging process to protect the battery’s lifespan and efficiency.

How Does an EV Onboard Charger Work?

There are two main types of charging methods that the OBC can use:

- Constant Current (CC): This method is efficient and fast, but there’s a risk of overcharging the EV battery, which could reduce its lifespan.

- Constant Voltage (CV): This method can charge the battery rapidly, but it might cause too much current to flow at the beginning of the charging process, potentially overheating the EV battery and shortening its lifespan.

The OBC typically starts with constant current charging for speed and efficiency to balance these factors. Then, when the battery voltage reaches a certain level, it switches to constant voltage charging. This strategy helps to optimize the charging process and prolong the battery’s lifespan.

Types of Onboard Chargers

Electric vehicles ‘ onboard chargers (OBCs) can be broadly classified into two types based on the power supply they use: single-phase (AC Onboard Chargers) and three-phase (DC Onboard Chargers).

AC Onboard Chargers (Single-Phase Onboard Chargers)

These chargers convert the Alternating Current (AC) from the power grid into Direct Current (DC) to charge the vehicle’s battery. They are typically used for home charging, and their power output ranges from 1.5 kW to 22 kW. The charging speed depends on the car’s onboard charger, with most accepting up to 7 kW.

DC Onboard Chargers (Three-Phase Onboard Chargers)

These chargers allow the vehicle to be charged directly with Direct Current (DC) from a charging station. They bypass the car’s onboard charger for faster charging. These chargers are typically found in public charging stations and can deliver power from 50 kW to over 350 kW.

Onboard chargers have varying requirements when it comes to the system level charging functions in battery electric versions (BEVs), plug-in hybrid electric vehicles (PHEVS), and in the near future fuel cell electric vehicles (FCEVS).

| Onboard Charger Parameters | Battery Electric Versions (BEVs) | Plug-in Hybrid Electric Vehicles (PHEVS) or Fuel Cell Electric Vehicles (FCEVS). |

|---|---|---|

| Output Power | <11kW in todays EVs, Adoption of 22kW in Fast Charging EVs | <7.2kW, Migration to high power for fast charging |

| AC Power | Single Phase and Three Phase Installation | Single Phase and Three Phase Installation |

| DC Fast Charge Bypass | Yes | Limited offerings, may see more in the near future |

| Cost | High Cost | Low Cost |

| Battery Pack Voltage | Currently Less than 400V, Some 800V, Wide adoption of 800V. | Less than 400V |

Onboard Charger in AC & DC Charging.

On an AC Charger, the Onboard EV Charger is found on the electric vehicle, while on a DC Charger, it is found on the electric vehicle itself.

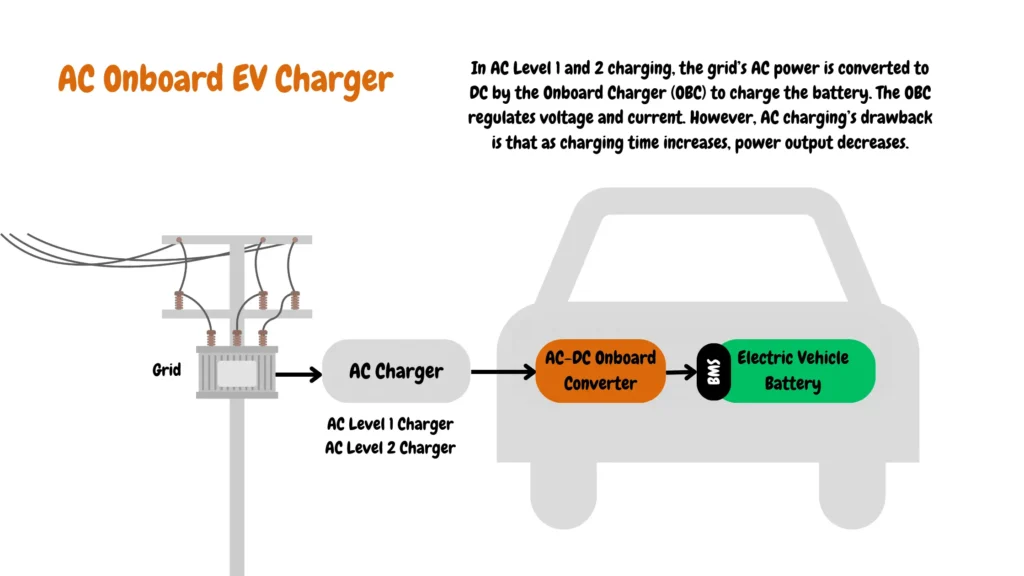

An Onboard Charger (OBC) in AC Charging

AC chargers with an inbuilt onboard charger are standard in-home EV chargers, also known as Level 1 and Level 2 home EV Chargers, which use AC Current with power outputs of 1.5 kW to 22 kW. AC Chargers rely on Onboard EV Charger electric vehicles to convert AC to DC currents.

The AC charger also depends on the Onboard EV Charger. to control the charging speeds, with most Onboard EV Chargers in electronic vehicles accepting up to 7kW.

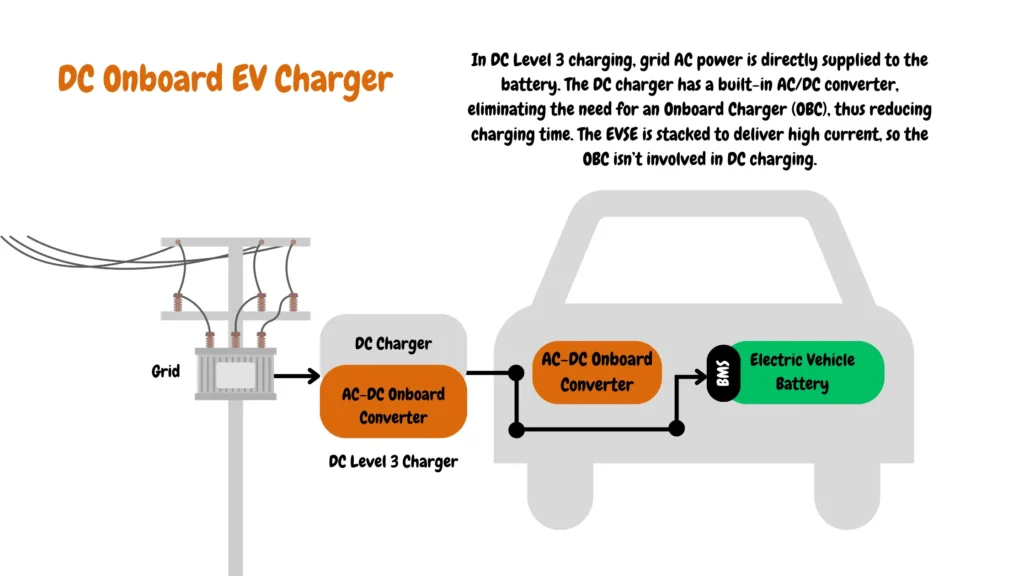

An Off-Board Charger (OBC) in DC Charging

DC chargers, also known as Level 3 or Fast EV chargers, have an off-board charger inbuilt that converts AC to DC in the chargers themselves; they are common in public stations and deliver power from 50 kW to over 350 kW and are known to bypass an electric vehicles Onboard EV Charger for faster charging.

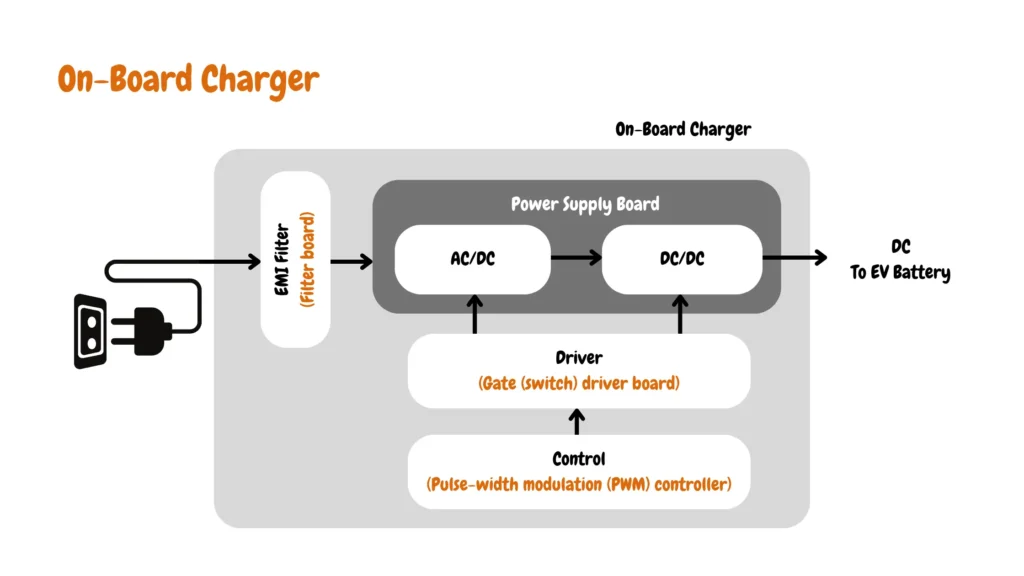

Onboard Charger Components

The Onboard Charger (OBC) in electric vehicles consists of four main printed circuit boards (PCBs) – Filter board, Power Supply Board, Control Board, and Driver Board. as shown in the image below:

Onboard Charger Filter Board

Also known as the EMI filter board, it filters out two types of Electromagnetic Interference (EMI) noise – Differential Mode (DM) and Common Mode (CM). DM noise is conducted on the line and neutral in opposite directions, while CM noise is conducted on both the line and neutral in the same direction.

Onboard Charger Power Supply Board

It comprises two parts – AC-DC and DC-DC. The AC-DC part, often called a rectifier, converts AC to DC and includes a Power Factor Correction (PFC) function to measure how efficiently electrical power is used. The DC-DC part converts DC to DC (either step up or down), maintaining a constant output voltage regardless of load current or variations in the supply voltage.

Onboard Charger Control Board

The control board, consisting of a microcontroller (MCU), acts as the ‘brain’ and sends Pulse-Width Modulation (PWM) signals to the driver board.

Onboard Charger Driver Board

The driver board interfaces between the MCU and the gates/switches on the power supply board, driving them to open or close.

James Ndungu is a certified EV charger installer with over five years of experience in EVSE selection, permitting, and installation. He holds advanced credentials, including certification from the Electric Vehicle Infrastructure Training Program (EVITP) and specialized training in EV charging equipment and installation, as well as diplomas in EV Technology and Engineering Fundamentals of EVs. Since 2021, James has tested dozens of EV chargers and accessories, sharing expert insights into the latest EV charging technologies.