50 amp circuit breakers are the most common for home level 2 EV chargers, making them the most public amperage for EV charging.

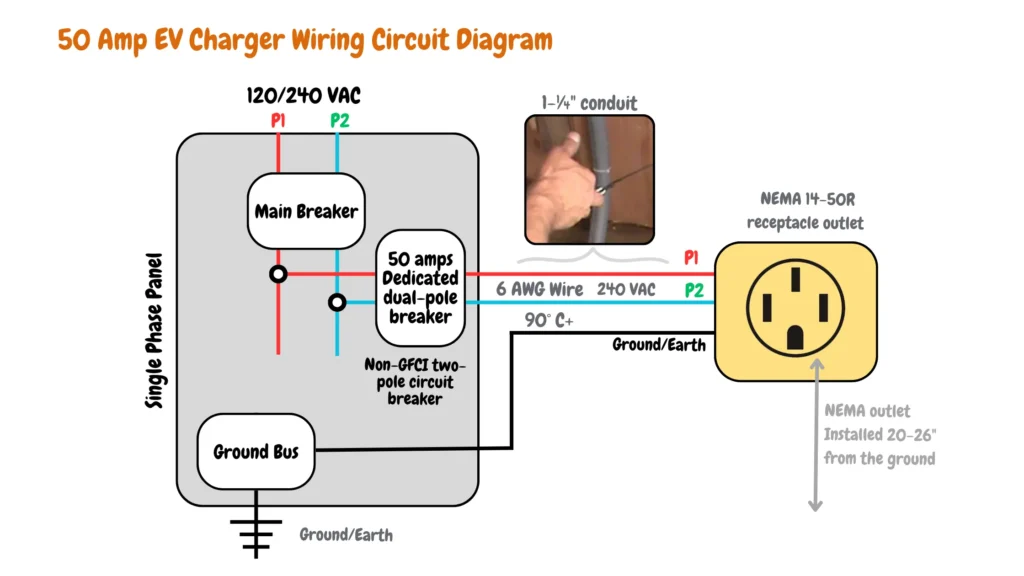

When installing an EV charger on a dedicated 50-amp circuit breaker, a common question arises: What 50 Amp EV Charger Wire Size should be used? This pertains to scenarios where the circuit breaker’s amperage is 50 amps and the voltage is 240 volts (for single-phase installations). This choice of wire size is crucial for connecting the circuit breaker with the NEMA 14-50 receptacle, NEMA 6-50, or the hardwired EV charger.

Table of Contents

- Wiring 50 Amps EV Charger Panels and Sub-Panels

- What Gauge Wire for 50 Amp EV Charger? (NEC 80% Rule)

- 50 Amp EV Charger Wire Temperature Rating.

- 50 Amps EV Charger Circuit Wire Length

Wiring 50 Amps EV Charger Panels and Sub-Panels

There are three main types of AWG sizes of wires that are used for wiring EV charging panels and sub-panels, they include:

| Wire Gauge (AWG) | Ampacity | Recommendation |

|---|---|---|

| 8 AWG | 50 A | Insufficient |

| 6 AWG | 65A | Recommended |

| 4 AWG | 85A | Excessive |

By looking at the wire gauges and their ampacity in the table above, one might conclude that using am 8AWG with an Ampacity of 50A is the right match, however, the wire size with an ampacity of 50 A will be considered insufficient due to the National Electrical Code (NEC) 80% Rule which states that the maximum loading capacity of electrical currents (circuits) should be 80%.

What Gauge Wire for 50 Amp EV Charger? (NEC 80% Rule)

According to NEC regulations, the 80% rule prevents overheating of electrical components and reduces the risk of fire hazards. In an EV charger installation, electrical components can experience heat buildup when the circuits operate at maximum capacity for an extended period, such as during EV charging. By limiting the circuit load to 80% of its rated capacity (in our case, 50A), the EV charger installation will have a safety margin that mitigates overheating and potential damage to the EV charger’s electrical system.

The calculation for determining the wire ampacity for a 50-amp circuit using the NEC 80% rule is as follows:

Wire Ampacity = Desired Current / 0.8

In this case:

Desired Current = 50 amps

Using the formula:

Wire Ampacity = 50 amps / 0.8 = 62.5 amps

50 Amp EV Charger Wire Temperature Rating.

In electrical wiring, the temperature rating refers to the maximum temperature that the insulation material surrounding the wire can withstand without degrading. The National Electrical Code (NEC) specifies temperature ratings for different types of wiring, and it’s crucial to select wires with an appropriate temperature rating to ensure safety and compliance with electrical codes.

For wiring an EV charger rated for 50 amps, it’s advisable to use wire with a temperature rating of from -40°C to +90°C. This ensures that the wire insulation can handle the heat generated by the current flowing through it without melting or becoming damaged. Using wire with a higher temperature rating provides a margin of safety and helps prevent overheating and potential fire hazards in the electrical system.

50 Amps EV Charger Circuit Wire Length

One of the reasons why its important to understand how long your subpanel wires should be is because of voltage drops as electricity travels through the wires. for every 100 feet of cable length, the voltage drops by 20%, which means when installing an EV charger subpanel you will need to elevate the amps by 20% to balance the drop.

James Ndungu is a certified EV charger installer with over five years of experience in EVSE selection, permitting, and installation. He holds advanced credentials, including certification from the Electric Vehicle Infrastructure Training Program (EVITP) and specialized training in EV charging equipment and installation, as well as diplomas in EV Technology and Engineering Fundamentals of EVs. Since 2021, James has tested dozens of EV chargers and accessories, sharing expert insights into the latest EV charging technologies.