EV charger wire gauge, also referred to as EV charger diameter or wire size, is the thickness of wires used in an electrical vehicle branch circuit. Wire size is typically measured in American Wire Gauge (AWG) in North America, or square millimeters (mm²) in metric systems.

According to the National Electrical Code (NEC) Article 210.19(A)(1) and Table 310.16, the correct wire gauge for an EV charger installation is determined primarily by the continuous load amperage rating of the dedicated EV charger circuit breaker, typically sized at 125% of the charger’s maximum continuous current.

Choosing the appropriate wire size is critical, as it ensures safe, continuous operation, minimizes voltage drop, and maintains compliance with NEC requirements for EV charging systems.

Table of Contents

- Key Takeaways

- Wire Sizing Best Practices for EV Charger Circuits

- EV Charger Wire Gauge Chart

- Common EV Charger Wire Gauge

- Factors to Consider When Choosing EV Charger Wire Gauge

- Copper vs. Aluminum EV Charger Wiring

- EV Charger Wiring and Installation Cost Breakdown (USA)

- Conclusions

Key Takeaways

According to NEC Article 625.41, overcurrent protection for feeders and branch circuits supplying Electric Vehicle Supply Equipment (EVSE), including bidirectional EVSE and wireless power transfer equipment (WPTE), must be rated for continuous loads and sized to at least 125% of the charger’s maximum continuous load.

A continuous load is an electrical load that runs at full power for three hours or more, according to the National Electrical Code (NEC Article 100). EV chargers are considered continuous loads because they often charge for long periods. This means the dedicated EV charger circuit breaker and wiring must be sized at least 125% of the charger’s maximum current (NEC Articles 210.20(A) and 625.41) to keep the system safe and prevent overheating.

In addition, NEC Article 210.19(A)(1) and Table 310.16 require that conductors supplying continuous loads also be sized to handle at least 125% of the charger’s rated current, ensuring safe operation under sustained use.

As a result, choosing the correct wire gauge requires considering both the electrical load and the total wire run length to maintain safe operation and comply with voltage drop limits and NEC safety standards.

The two summary tables below list the minimum copper wire sizes (Appropriately rated, like THHN/THWN-2 or NM-B) required for Level 1 (120V) and Level 2 (240V) EV charger circuits, based on NEC requirements.

Level 1 EV Charger Wire Sizes

| Charger Amperage | Circuit Breaker Size | Voltage | Minimum Wire Size | Outlet Type | Power Output |

|---|---|---|---|---|---|

| 12 amps | 15 amps | 120V | 14 AWG (≈ 2.08 mm²) | NEMA 5-15 (Standard) | 1.44 kW |

| 16 amps | 20 amps | 120V | 12 AWG (≈ 3.31 mm²) | NEMA 5-20 (T-slot) | 1.92 kW |

Level 2 EV Charger Wire Sizes

| EV Charger Rating (Continuous Loads) | Power Rating of EV Charger (kW) | Voltage | EV Charger Dedicated Breaker Size (rated at least 125% of the load) | Hot Wire Gauge (AWG) (Copper) | EV Charger Wire Size (mm²) |

|---|---|---|---|---|---|

| 12 Amp | 2.88 kW | 240V | 15 Amp | 14 | 2.08 mm² |

| 16 Amp | 3.84 kW | 240V | 20 Amp | 12 | 3.31 mm² |

| 20 Amp | 4.80 kW | 240V | 25 Amp | 10 | 5.26 mm² |

| 24 Amp | 5.76 kW | 240V | 30 Amp | 10 | 5.26 mm² |

| 28 Amp | 6.72 kW | 240V | 35 Amp | 8 | 8.37 mm² |

| 32 Amp | 7.68 kW | 240V | 40 Amp | 8 | 8.37 mm² |

| 36 Amp | 8.64 kW | 240V | 45 Amp | 6 | 13.3 mm² |

| 40 Amp | 9.60 kW | 240V | 50 Amp | 6 | 13.3 mm² |

| 48 Amp | 11.52 kW | 240V | 60 Amp | 4 | 21.2 mm² |

| 56 Amp | 13.44 kW | 240V | 70 Amp | 4 | 21.2 mm² |

| 64 Amp | 15.36 kW | 240V | 80 Amp | 3 | 26.7 mm² |

| 72 Amp | 17.28 kW | 240V | 90 Amp | 2 | 33.6 mm² |

| 80 Amp | 19.20 kW | 240V | 100 Amp | 2 | 33.6 mm² |

EV Charger Wiring & Installation – Quick Cost Summary

Installing a residential EV charger typically costs $6–$40+ per foot for wiring and conduit, depending on distance, wire thickness, and installation type (e.g., surface vs. buried). Electrical panel upgrades may add $500–$2,500+, while permits and inspections range from $50–$500+. Commercial EV charger installations cost 15–30% more. Always use a licensed electrician for safety, insurance, and code compliance.

Wire Sizing Best Practices for EV Charger Circuits

Always increase wire gauge (i.e., use thicker wire) for longer distances or warmer environments to minimize EV charging voltage drop and reduce the risk of overheating. Solid Copper conductors are recommended for EV charging installations due to their superior conductivity, thermal stability, and long-term reliability.

Before installation, verify that your EV charger terminals and any connected EV charging accessories, such as circuit breakers or disconnects, are rated for the wire size you plan to use. Avoid mixing different wire gauges within the same EV charger circuit, as this can lead to uneven current flow, elevated resistance, and localized overheating, particularly under continuous high loads. Thinner segments effectively become a bottleneck, compromising both safety and performance.

To ensure a code-compliant and secure installation, terminate only one wire per terminal, and maintain consistent wire gauge throughout the entire branch circuit unless specifically engineered for transitions.

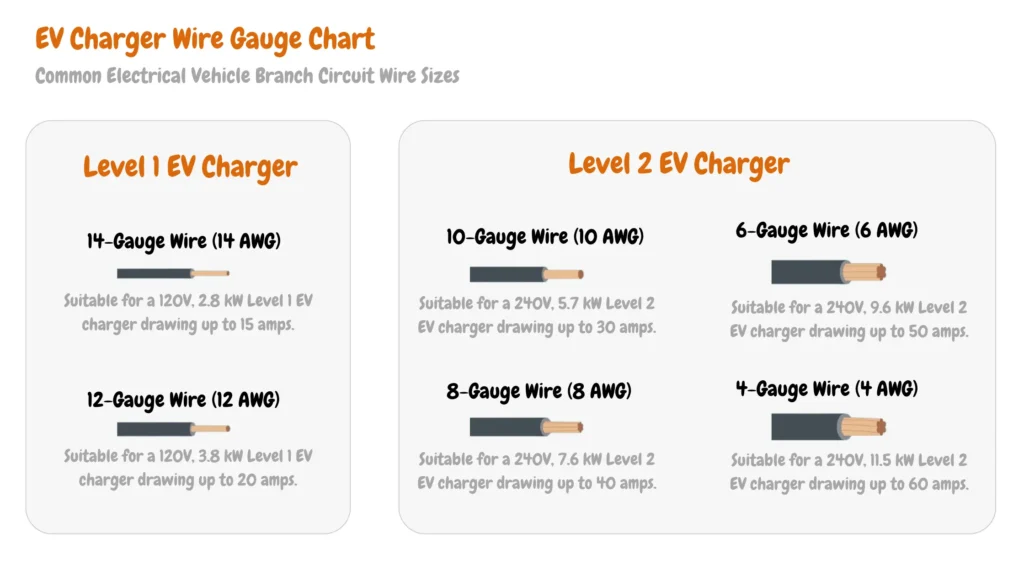

EV Charger Wire Gauge Chart

The EV Charger Wire Gauge Chart below lists common electrical vehicle branch circuit wire sizes for Level 1 and Level 2 EV chargers. It shows the wire image and specifies the appropriate wire gauges (AWG) for different power levels and current draws.

Common EV Charger Wire Gauge

EV charger wire gauge is determined by the amperage of the circuit breaker in an electric vehicle’s branch circuit. The table below summarizes the common EV charger wire gauge used in EV charger installations.

| EV Charger Rating (Continuous Loads) | Power Rating of EV Charger (kW) | EV Charger Dedicated Breaker Size (rated at least 125% of the load) | Hot Wire Gauge (AWG) (Copper) | EV Charger Wire Size (mm²) |

|---|---|---|---|---|

| 12 Amp | 1.44 kW/2.88 kW | 15 Amp | 14 | 2.08 mm² |

| 16 Amp | 1.92 kW/3.84 kW | 20 Amp | 12 | 3.31 mm² |

| 20 Amp | 4.80 kW | 25 Amp | 10 | 5.26 mm² |

| 24 Amp | 5.76 kW | 30 Amp | 10 | 5.26 mm² |

| 28 Amp | 6.72 kW | 35 Amp | 8 | 8.37 mm² |

| 32 Amp | 7.68 kW | 40 Amp | 8 | 8.37 mm² |

| 36 Amp | 8.64 kW | 45 Amp | 6 | 13.3 mm² |

| 40 Amp | 9.60 kW | 50 Amp | 6 | 13.3 mm² |

| 48 Amp | 11.52 kW | 60 Amp | 4 | 21.2 mm² |

| 56 Amp | 13.44 kW | 70 Amp | 4 | 21.2 mm² |

| 64 Amp | 15.36 kW | 80 Amp | 3 | 26.7 mm² |

| 72 Amp | 17.28 kW | 90 Amp | 2 | 33.6 mm² |

| 80 Amp | 19.20 kW | 100 Amp | 2 | 33.6 mm² |

Here are some common usages for the various EV charger wire gauges:

Plug-In EV Charger Wire Sizes

The National Electrical Code (NEC) specifies that the maximum amperage for a plug-in EV charger is 40 amps, requiring a 50-amp circuit breaker. Plug-in chargers are limited by the capacity of NEMA outlets and the safety of removable connections.

Recommended Wire Sizes for Plug-In EV Chargers

| Plug-In EV Charger Rating (Amps) | Power Rating (kW) | Breaker Size (Amps) | Wire Gauge (AWG) | Wire Size (mm²) | EV Charger Outlet |

|---|---|---|---|---|---|

| 12 A | 1.44 kW | 15 A | 14 | 2.08 mm² | NEMA 5-15 (120V) |

| 12 A | 2.88 kW | 15 A | 14 | 2.08 mm² | NEMA 6-15 (240V) |

| 16 A | 1.92 kW | 20 A | 12 | 3.31 mm² | NEMA 5-20 (120V) |

| 16 A | 3.84 kW | 20 A | 12 | 3.31 mm² | NEMA 6-20 (240V) |

| 20 A | 4.80 kW | 25 A | 10 | 5.26 mm² | NEMA 6-30 (240V) |

| 24 A | 5.76 kW | 30 A | 10 | 5.26 mm² | NEMA 6-30 (240V) |

| 32 A | 7.68 kW | 40 A | 8 | 8.37 mm² | NEMA 14-50 (240V) |

| 40 A | 9.60 kW | 50 A | 6 | 13.3 mm² | NEMA 14-50 or NEMA 6-50 |

To assist you with the installation process of plug-in EV charger outlets, we recommend checking out our comprehensive guide on installing NEMA outlets for plug-in EV chargers. This guide covers everything you need to know, including how to select the correct outlet for your charger’s amperage, determine the proper dedicated circuit breaker size, choose the right outlet wiring and wire gauge, and provide installation tips.

Hardwired EV Charger Wire Sizes

Hardwired chargers are permanently installed, providing higher power capacity and supporting faster charging rates compared to plug-in chargers. They are ideal for chargers exceeding 40 amps or when a clean, permanent setup is desired.

Recommended Wire Sizes for Hardwired EV Chargers

| Hardwired EV Charger Rating (Continuous Loads) | Power Rating of EV Charger (kW) | EV Charger Dedicated Breaker Size (rated at least 125% of the load) | Hot Wire Gauge (AWG) (Copper) | EV Charger Wire Size (mm²) |

|---|---|---|---|---|

| 12 Amp | 1.44 kW/2.88 kW | 15 Amp | 14 | 2.08 mm² |

| 16 Amp | 1.92 kW/3.84 kW | 20 Amp | 12 | 3.31 mm² |

| 20 Amp | 4.80 kW | 25 Amp | 10 | 5.26 mm² |

| 24 Amp | 5.76 kW | 30 Amp | 10 | 5.26 mm² |

| 28 Amp | 6.72 kW | 35 Amp | 8 | 8.37 mm² |

| 32 Amp | 7.68 kW | 40 Amp | 8 | 8.37 mm² |

| 36 Amp | 8.64 kW | 45 Amp | 6 | 13.3 mm² |

| 40 Amp | 9.60 kW | 50 Amp | 6 | 13.3 mm² |

| 48 Amp | 11.52 kW | 60 Amp | 4 | 21.2 mm² |

| 56 Amp | 13.44 kW | 70 Amp | 4 | 21.2 mm² |

| 64 Amp | 15.36 kW | 80 Amp | 3 | 26.7 mm² |

| 72 Amp | 17.28 kW | 90 Amp | 2 | 33.6 mm² |

| 80 Amp | 19.20 kW | 100 Amp | 2 | 33.6 mm² |

For those installing a hardwired EV charger, we recommend checking out our comprehensive guide on hardwired EV charger installation. This guide covers essential topics like selecting the correct wire gauge for your charger’s amperage, determining the appropriate dedicated circuit breaker size, and following expert installation practices.

Level 1 EV Charger Wire Size

These are the minimum wire sizes required for installing Level 1 EV chargers on 120V circuits, based on the 80% continuous load rule per NEC guidelines.

12-Amp Level 1 Charging (NEMA 5-15) – Use 14 AWG Copper Wire

A 12-amp EV charger on a 120V NEMA 5-15 outlet requires 14 AWG copper wire (2.08 mm²) on a 15-amp circuit. This setup provides up to 1.44 kW of charging power, adding 3 to 5 miles of range per hour.

16-Amp Level 1 Charging (NEMA 5-20) – Use 12 AWG Copper Wire

A 16-amp EV charger on a 120V NEMA 5-20 outlet (T-slot) requires 12 AWG copper wire (3.31 mm²) on a dedicated 20-amp circuit. It delivers up to 1.92 kW and adds 4 to 6.5 miles of range per hour.

Level 2 EV Charger Wire Size

Level 2 EV chargers operate at 240V, offering significantly faster charging speeds than Level 1 chargers, making them ideal for daily at-home use. These chargers require higher amperage and thicker wires to accommodate the increased power demand and the continuous load of Level 2 charging.

Wire Size Recommendations for Level 2 EV Chargers

| Level 2 EV Charger Rating (Continuous Loads) | Power Rating of EV Charger (kW) | EV Charger Dedicated Breaker Size (rated at least 125% of the load) | Hot Wire Gauge (AWG) (Copper) | EV Charger Wire Size (mm²) |

|---|---|---|---|---|

| 12 Amp | 2.88 kW | 15 Amp | 14 | 2.08 mm² |

| 16 Amp | 3.84 kW | 20 Amp | 12 | 3.31 mm² |

| 20 Amp | 4.80 kW | 25 Amp | 10 | 5.26 mm² |

| 24 Amp | 5.76 kW | 30 Amp | 10 | 5.26 mm² |

| 28 Amp | 6.72 kW | 35 Amp | 8 | 8.37 mm² |

| 32 Amp | 7.68 kW | 40 Amp | 8 | 8.37 mm² |

| 36 Amp | 8.64 kW | 45 Amp | 6 | 13.3 mm² |

| 40 Amp | 9.60 kW | 50 Amp | 6 | 13.3 mm² |

| 48 Amp | 11.52 kW | 60 Amp | 4 | 21.2 mm² |

| 56 Amp | 13.44 kW | 70 Amp | 4 | 21.2 mm² |

| 64 Amp | 15.36 kW | 80 Amp | 3 | 26.7 mm² |

| 72 Amp | 17.28 kW | 90 Amp | 2 | 33.6 mm² |

| 80 Amp | 19.20 kW | 100 Amp | 2 | 33.6 mm² |

EV Charger Ground Conductor Size

The ground conductor in an EV charger circuit acts as a pathway for excess electrical current to safely flow to ground, preventing electrical shock and damage to equipment. Its size is typically based on the EV charger’s circuit breaker rating, as outlined in NEC Table 250.122.

In my EV charger installations, I always make sure to use the correct gauge ground conductor based on the dedicated EV charger circuit breaker size (not the load or wire size), not only to provide a safe pathway for excess electrical current, but also to ensure it can handle EV charging ground-fault or leakage current without overheating or failure, preserving the integrity and safety of the entire grounding system.

| EV Charger Rating (Continuous Loads) | EV Charger Dedicated Breaker Size (rated at least 125% of the load) | Grounding Conductor (Copper) | Grounding Conductor (Aluminum) |

|---|---|---|---|

| 12 Amp | 15 Amp | 14 AWG | 12 AWG |

| 16 Amp | 20 Amp | 12 AWG | 10 AWG |

| 20 Amp | 25 Amp | 10 AWG | 8 AWG |

| 24 Amp | 30 Amp | 10 AWG | 8 AWG |

| 28 Amp | 35 Amp | 10 AWG | 8 AWG |

| 32 Amp | 40 Amp | 10 AWG | 8 AWG |

| 36 Amp | 45 Amp | 10 AWG | 8 AWG |

| 40 Amp | 50 Amp | 10 AWG | 8 AWG |

| 48 Amp | 60 Amp | 10 AWG | 8 AWG |

| 56 Amp | 70 Amp | 8 AWG | 6 AWG |

| 64 Amp | 80 Amp | 8 AWG | 6 AWG |

| 72 Amp | 90 Amp | 8 AWG | 6 AWG |

| 80 Amp | 100 Amp | 8 AWG | 6 AWG |

For more detailed installation guidelines, refer to our EV Charger Earthing Guide.

Factors to Consider When Choosing EV Charger Wire Gauge

Electric Vehicle Branch Circuit Load (Charging Station Power)

The primary factor influencing your choice of EV charger wire gauge is the electrical load of your EV’s branch circuit. To determine the appropriate wire gauge, you must first understand the total electrical load of your EV charger.

According to the National Electrical Code (NEC), the total current draw must be less than 80% of the circuit breaker’s rated limit due to derating requirements for continuous loads.

The higher the electric vehicle branch circuit load (charging station power), the larger the cable size should be to support the electrical current flowing to the charger.

EV Charger Circuit Breaker Size.

The circuit breaker sizing for Electric Vehicle Supply Equipment (EVSE) is governed by the National Electrical Code (NEC), particularly with continuous loads experienced during EV charging.

According to NEC Article 100, a continuous load is defined as one where the maximum current is expected to flow for three hours or more, exactly the case for most EV charging sessions.

To prevent overheating and ensure long-term safety, NEC Section 625.41 requires that the branch circuit and overcurrent protection device be sized to at least 125% of the EV charger’s rated current.

This 125% rule, often referred to as the “80% rule,” ensures the circuit operates at no more than 80% of its rated capacity under continuous load, leaving a built-in safety margin.

For example, a Level 2 EV charger rated at 40 amps would require a 50-amp breaker (40A × 1.25) and properly sized conductors, as confirmed in NEC Article 210.

This principle is essential for preventing thermal overload, maintaining code compliance, and ensuring the long-term safety of your EV charging installation.

Distance from Electrical Panel

The distance between the electrical panel and the EV charger significantly impacts cable selection, as longer runs increase voltage drop and require larger wire gauges to maintain safe and efficient charging.

EV Charger Voltage Drop

When choosing the right wire gauge for your EV charger, voltage drop is one of the most important factors. The National Electrical Code (NEC) recommends a maximum voltage drop of 3% for household circuits (called branch circuits). This guideline affects both the wire size (gauge) and the length you need for your EV charger installation.

In our EV charger voltage drop tests, we calculated the proper wire sizes and maximum cable lengths needed to stay within the 3% voltage drop limit. These tests included complex installations with long cable runs, especially in outdoor and underground wiring setups.

The tables below show the maximum cable lengths you can use for Level 1 and Level 2 EV chargers, based on wire gauge (AWG) and circuit voltage, while still staying within the safe 3% voltage drop range.

120V EV Chargers (Level 1 EV Charger) Circuit Conductors Sizing

| Wire Gauge | Length |

|---|---|

| 14 AWG | 50 Feet |

| 12 AWG | 60 Feet |

| 10 AWG | 64 Feet |

| 8 AWG | 76 Feet |

| 6 AWG | 94 Feet |

240V EV Chargers (Level 2 EV Charger) Circuits Conductors Sizing

| Wire Gauge | Length |

|---|---|

| 14 AWG | 100 Feet |

| 12 AWG | 120 Feet |

| 10 AWG | 128 Feet |

| 8 AWG | 152 Feet |

| 6 AWG | 188 Feet |

Future Electric Vehicle Branch Circuit Expansion

If you plan to expand your electrical vehicle branch circuit, it’s wise to install a wire gauge that accommodates future growth, for example, when installing a Level 1 EV charger, but in the future, you plan to install a Level 2 EV charger it’s wise to use Level 2 EV charger wire size to save you from costly upgrades down the road.

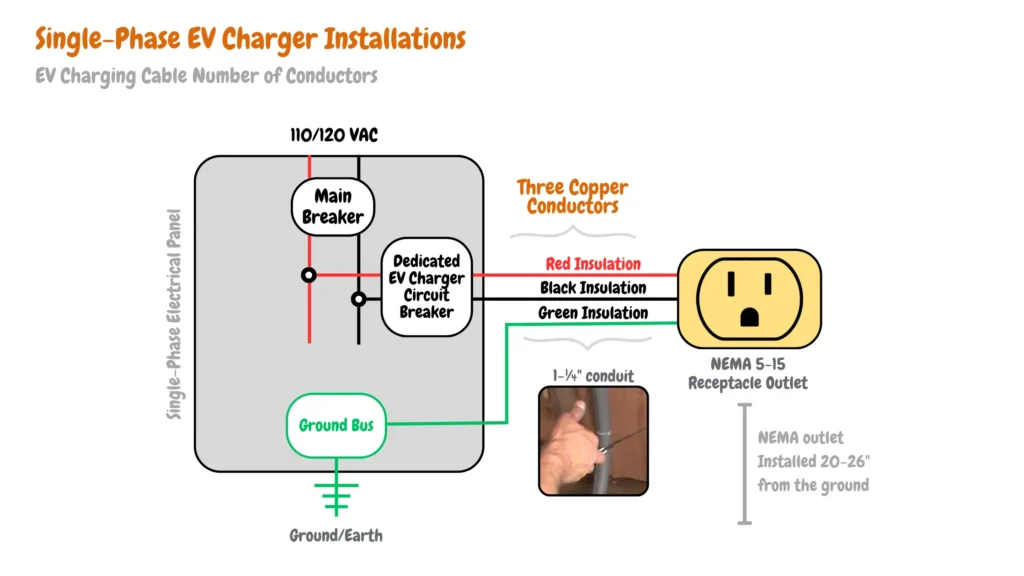

Number of Conductors in EV Charger Branch Circuit

The number of conductors in an EV charger branch circuit depends not only on the type of installation, such as a hardwired EV charger installation or plug-in EV charger installation, but also on the charger’s specifications and whether the system is single-phase or three-phase. Factors like the need for a neutral, support for load sharing, or integrated smart features also influence conductor requirements.

For single-phase EV charger installations, three conductors are common: phase, neutral, and ground, as shown in the single-phase electric vehicle branch circuit below:

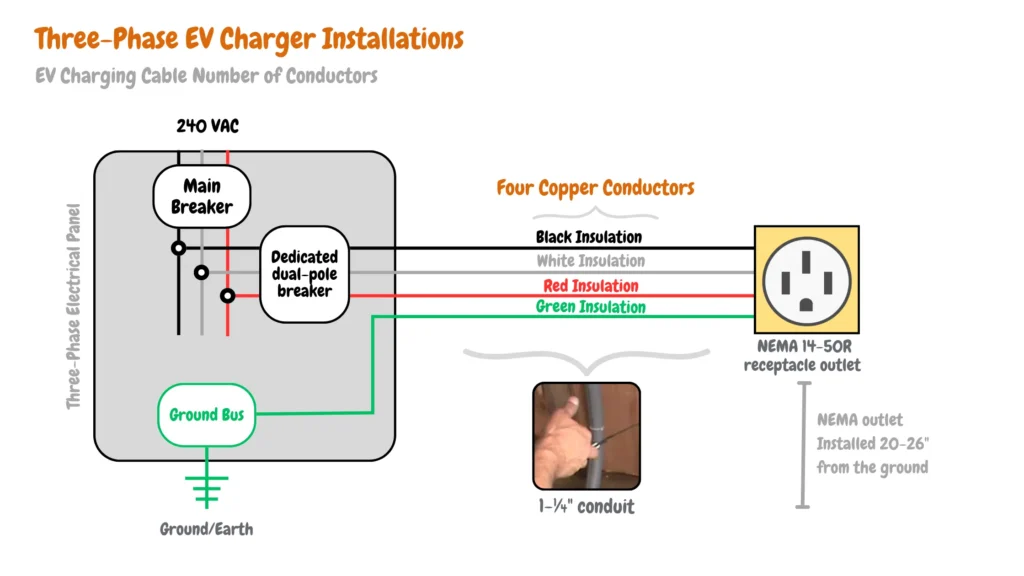

For three-phase EV charger installations, four conductors are common: two phase wires, one neutral, and one ground. This is illustrated in the three-phase 240V EV branch circuit example on the subpanel below.

These conductors are bundled within a single cable and are typically composed of multiple metal strands to ensure flexibility and durability. The choice between single-phase and three-phase installations depends on your EV charger branch circuit and the specifications of the charging station.

Learn more about wiring an electric vehicle branch circuit:

Copper vs. Aluminum EV Charger Wiring

When considering EV charger installations, copper wiring surpasses aluminum due to its superior thermal properties, which significantly impact performance and safety.

Here’s why we recommend copper wire for EV charger installation:

- Superior Conductivity: Copper offers significantly better conductivity than aluminum. This translates to lower resistive losses, minimizing heat generation within the cable. This is crucial for EV chargers that deliver high currents for extended periods.

- Enhanced Safety: Lower heat generation with copper reduces the risk of overheating and potential fire hazards, especially during longer EV charging sessions.

- Reliable Connections: Copper’s superior malleability allows for tighter and more reliable connections at the charger terminals, further enhancing safety and preventing power loss.

EV Charger Wiring and Installation Cost Breakdown (USA)

The table below outlines typical cost ranges for EV charger installations across various wiring scenarios. It includes exposed interior runs, concealed wiring in finished spaces, and underground conduit installations. Costs account for standard materials, labor, and key variables such as wire gauge, accessibility, and wall or soil conditions.

Additional components like trenching, conduit installation, electrical panel modifications, and permitting are also detailed. Electrician hourly rates vary significantly by region and license type, influencing overall project costs. Figures reflect standard practices for residential and commercial EV charger installations.

| Category | Residential (Approx. Range) | Commercial (Approx. Range) | Key Notes & Details |

|---|---|---|---|

| I. Materials (per Linear Foot) | |||

| Copper Wire (Bare Cost) | $0.50 – $4.50+ (per gauge) | $0.70 – $6.00+ (per gauge) | Highly dependent on AWG gauge. Larger gauges (e.g., 2 AWG) are at the higher end. Smaller gauges (e.g., 14 AWG) are at the lower end. Includes THHN/THWN-2, Romex. Prices fluctuate. |

| Conduit (Material Only) | $0.70 – $8.00+ (per type/size) | $1.00 – $12.00+ (per type/size) | PVC (cheaper, for exposed/underground). EMT (Electrometallic Tubing – common for exposed/commercial). RMC (Rigid Metal Conduit – most durable, expensive, often outdoors/industrial). |

| II. Labor (Hourly Rates) | |||

| Electrician Hourly Rate | $60 – $120/hour | $80 – $160+/hour | Varies significantly by region, license type (journeyman vs. master), and company overhead. Many have minimum call-out fees ($100-$250). |

| III. Installation Services (Inclusive of Labor & Standard Materials) | |||

| Interior Wiring (Accessible/Exposed) | $6 – $12/linear ft. | $9 – $18/linear ft. | For runs in unfinished basements, attics, and garages where access is easy. Includes wire, basic fittings, and labor for pulling/securing. Assumes standard gauge (e.g., 14-10 AWG). Heavier gauges (e.g., 6-2 AWG) will be higher. |

| Interior Wiring (Concealed/Finished) | $12 – $35+/linear ft. | $18 – $45+/linear ft. | For runs inside finished walls/ceilings, requiring cutting and patching drywall, or complex routing. Labor-intensive. |

| Underground Wiring (Installed) | $15 – $40+/linear ft. | $20 – $50+/linear ft. | Includes all aspects: trenching, conduit material & installation, wire, and backfill. Depth requirements vary (e.g., 18″ for rigid PVC, 24″ for RMC). Soil conditions are a major factor. |

| Component: Trenching (Labor Only) | $4 – $15/linear ft. | $6 – $20/linear ft. | Cost to dig the trench for underground runs. Can be higher for rock, roots, or difficult access. May exclude debris removal. |

| Component: Conduit Installation (UG) | +$5 – $15/linear ft. | +$8 – $20/linear ft. | Cost to dig the trench for underground runs. It can be higher for rock, roots, or difficult access. May exclude debris removal. |

| Electrical Panel Work (Labor & Parts) | $150 – $800+ (per breaker/mod) | $300 – $1,500+ (per breaker/mod) | For adding new breakers, ensuring panel capacity, or minor subpanel work. Major panel upgrades (e.g., increasing service amperage) can cost $2,000 – $5,000+. |

| Permits & Inspections | $75 – $500+ | $200 – $1,000+ | Mandatory for safety and code compliance. Costs vary by municipality, project scope, and electrical load added. Excludes potential reinspection fees. |

| IV. Total Project Cost (Conceptual) | |||

| Typical Small Project (e.g., New Outlet) | $250 – $800+ | Varies widely | Depends on location, complexity, and specific components. |

| EV Charger Installation | $500 – $2,500+ (Level 2) | $800 – $4,000+ (Level 2/3) | Highly variable based on distance to panel, panel capacity, and outdoor vs. indoor. |

| Whole-Home Rewire | $8,000 – $25,000+ | Varies widely | Highly complex and project-specific. |

Conclusions

In conclusion, selecting the correct wire gauge for your EV charger is essential to ensure long-term safety, code compliance, and reliable charging performance. Key factors include the charger’s amperage, circuit voltage, run length, wire material (copper vs. aluminum), and future upgrade potential. Proper sizing not only reduces heat buildup and voltage drop but also supports the continuous load demands of EV charging. A well-designed circuit protects your investment and ensures your charging system operates efficiently and safely for years to come.

James Ndungu is a certified EV charger installer with over five years of experience in EVSE selection, permitting, and installation. He holds advanced credentials, including certification from the Electric Vehicle Infrastructure Training Program (EVITP) and specialized training in EV charging equipment and installation, as well as diplomas in EV Technology and Engineering Fundamentals of EVs. Since 2021, James has tested dozens of EV chargers and accessories, sharing expert insights into the latest EV charging technologies.