Your complete guide to choosing, installing, and maintaining the right GFCI Breaker for EV Charger, ensuring safety, compliance, and peak performance.

When installing a home EV charger, safety isn’t just about selecting an EV charger with built-in safety features; it’s also about ensuring your EV charger installation complies with local codes. The NEC (National Electrical Code) sets strict guidelines for how your EV charging branch circuit should be designed, and one of the most important requirements involves installing a dedicated Ground Fault Circuit Interrupter (GFCI) circuit breaker on the branch circuit serving your EV charger.

Table of Contents

What Is a GFCI Circuit Breaker for EV Chargers?

Introduction

At Electric Vehicle Geek, our mission is to promote safe EV charging, which includes safe EV charger installations. Recently, we’ve seen a surge in reader questions about GFCI protection for EV chargers, especially hardwired models, as many have heard about the National Fire Protection Association (NFPA) 70 2026 proposal that may require GFCI breakers for all EV charger installations.

GFCI Requirements for EV Chargers: Current Rules and Upcoming Changes

Under the 2023 NEC, Article 625.54 requires GFCI protection only for Plug-in EV chargers, while Article 210.8(A) applies to EV Charger outlets located outdoors, in garages, or within 6 feet of water. In practice, this means GFCI is required only for plug-in chargers and EV charger installations in areas at risk of ground faults, such as wet or outdoor installations.

The topic of GFCI breakers for EV chargers is gaining momentum with the NFPA 70 2026 proposal, which could mandate GFCI protection for all permanently installed EV chargers.

While many hardwired chargers include internal GFCI-like protection (CCID) that can reset automatically after a trip, NFPA 70 2026 requires standard GFCI protection for EV charger installations at 150 volts or less to ground. Installations exceeding 150 volts to ground must use special-purpose ground-fault circuit interrupters (SPGFCIs), though these devices are not yet widely available.

Following public feedback during the 2026 NEC drafting process, installations exceeding 150 volts to ground have been granted an extension until January 1, 2029, allowing manufacturers time to develop products that support bidirectional current flow.

Bi-directional EV chargers capable of sending power back to the grid are exempt from this requirement because they continuously verify solid grounding and use higher-threshold ground-fault protection tailored for their unique operation.

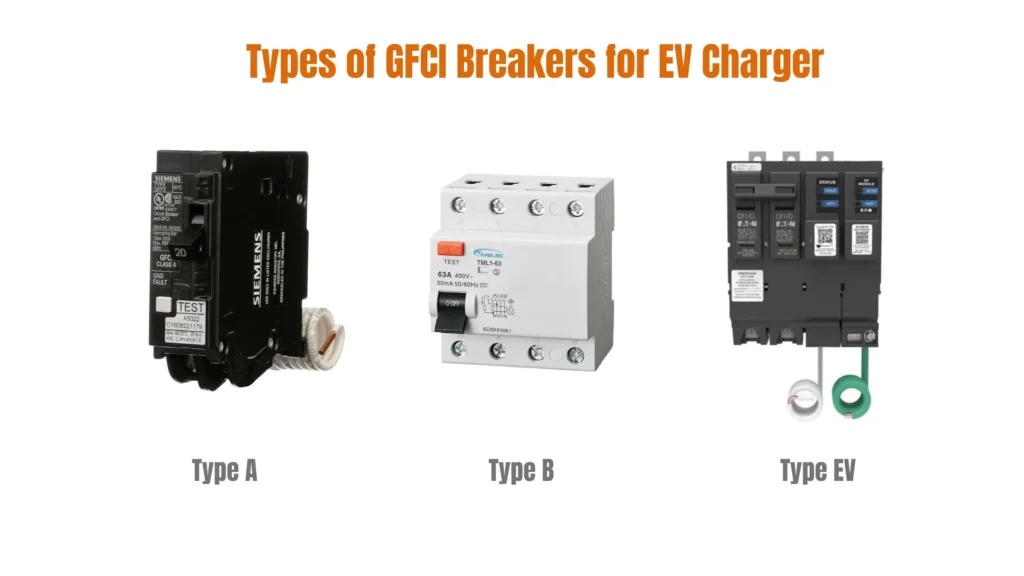

Types of GFCI Breakers for EV Charger

There are four types of GFCI breakers for EV chargers, classified by the types of leakage current they detect: Type A, Type B, Type EV, and SPGFCI (Special-Purpose Ground-Fault Circuit Interrupter).

Each type is designed to detect different fault currents and is suited for specific EV charger installations.

| GFCI Type | Leakage Current Detected | Trip Threshold | Key Notes |

|---|---|---|---|

| Type A | AC and pulsating DC residual currents | 4–6 mA | Standard GFCI protection may nuisance trip with some EV chargers’ self-tests |

| Type B | AC, pulsating DC, and smooth DC leakage | 6 mA or higher (varies) | Detects smooth DC leakage; better for EV chargers without internal protection |

| Type EV | AC, pulsating DC, and smooth DC leakage all enhanced for EV-specific leakage currents. | 20 mA or 30 mA | Designed for EVs; compatible with charger internal CCID protection |

| SPGFCI | AC, pulsating DC, and smooth DC leakage are all enhanced for high voltage leakage currents. | 20 mA or higher | Designed for EVs; compatible with charger internal CCID protection, especially higher-voltage or bidirectional chargers |

Type A Breakers

Type A breakers detect AC sinusoidal and pulsating DC residual currents, typically tripping at 4–6 milliamperes (mA). While they provide essential safety, Type A breakers are not ideal or recommended for EV charging due to frequent nuisance tripping. Additionally, they suffer from the “blinding” problem; smooth DC currents during EV charging above approximately 6 mA can saturate the breaker’s internal magnetic core, rendering it unable to detect potentially dangerous AC faults.

I’ve seen this firsthand while testing EV chargers on our test bench, where smart chargers performing self-tests at initial connection or during charging often caused nuisance tripping shortly after installation, especially when paired with older or generic Class A breakers. The issue wasn’t the chargers themselves, but the breakers’ inability to distinguish normal EVSE self-test currents from actual faults.

To mitigate this, I recommend Type B or Type EV GFCI breakers designed to handle both AC and smooth DC leakage currents common in EV chargers, especially if your EV charger doesn’t have inbuilt GFCI protection.

Type B Breakers

Type B breakers detect sinusoidal AC, pulsating DC, and smooth DC residual currents, making them better suited for EV chargers that produce complex leakage currents and don’t have built-in ground fault protection. They also trip at around 6 mA but offer enhanced sensitivity to the DC leakage produced by electronic components inside a home EV charger.

During our EV charger testing and installations, we observed that standard GFCI breakers with low trip thresholds (4–6 mA) often trip up first when paired with chargers featuring built-in protection set around 15–20 mA, because the breaker trips before the charger’s internal protection can respond.

For chargers without internal GFCI, we recommend using a Type B breaker, while chargers with built-in protection perform best with Type EV, or Special-Purpose GFCI (SPGFCI) that trips at higher leakage levels, minimizing false trips and ensuring reliable, safe charging.

Type EV Breakers

Type EV GFCI breakers are specifically designed for electric vehicle charging. These breakers detect a broad range of leakage currents, including sinusoidal AC, pulsating DC, and smooth DC, ensuring comprehensive protection tailored to EV charging systems.

Unlike Type A and B GFCIs, Type EV are often designed with a higher trip threshold (such as 20 mA or 30 mA) to work in harmony with the EV charger’s built-in ground-fault protection (CCID20), this coordination helps prevent nuisance tripping caused by the minor leakage currents generated during normal charger operation, providing a more reliable charging experience.

Special-Purpose Ground-Fault Circuit Interrupters (SPGFCIs)

A Special-Purpose Ground-Fault Circuit Interrupter (SPGFCI) is a specialized type of GFCI designed specifically for EV charging circuits with a voltage to ground greater than 150 volts.

Like Type B GFCI breakers, SPGFCIs detect sinusoidal AC, pulsating DC, and smooth DC leakage currents. However, they feature a higher trip threshold (typically 20 mA or more), helping prevent nuisance tripping caused by the minor, non-hazardous leakage currents that EV chargers can produce during normal operation.

This higher threshold and voltage rating make SPGFCIs especially suited for modern EV charging circuits with elevated voltage requirements.

The upcoming NFPA 70 2026 proposal may require SPGFCIs for all EV chargers, ensuring panel-level protection works seamlessly with charger safety features to provide a more reliable and safer charging experience.

EV Charger GFCI Breaker Installation

Now that you understand the different types of EV charger GFCI breakers, let’s discuss how to install them by highlighting some of the most important factors to consider when installing a dedicated GFCI breaker for EV charging.

Choose the Correct GFCI Breaker Type.

Selecting the right dedicated GFCI breaker for EV charging is crucial for both safety and compliance with electrical codes. For EV chargers, it’s important to choose a dedicated EV charger breaker that matches your system’s voltage and specific requirements.

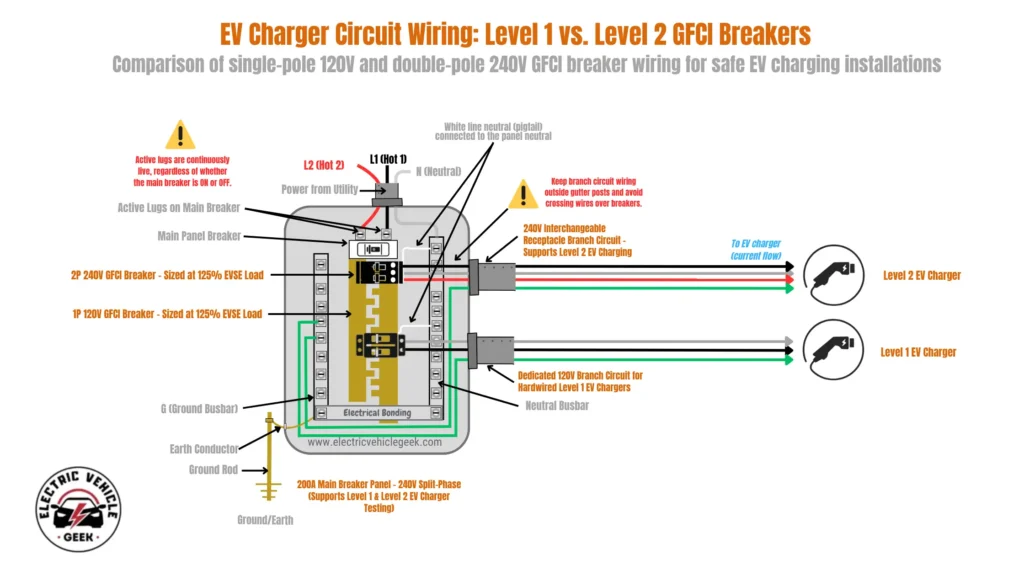

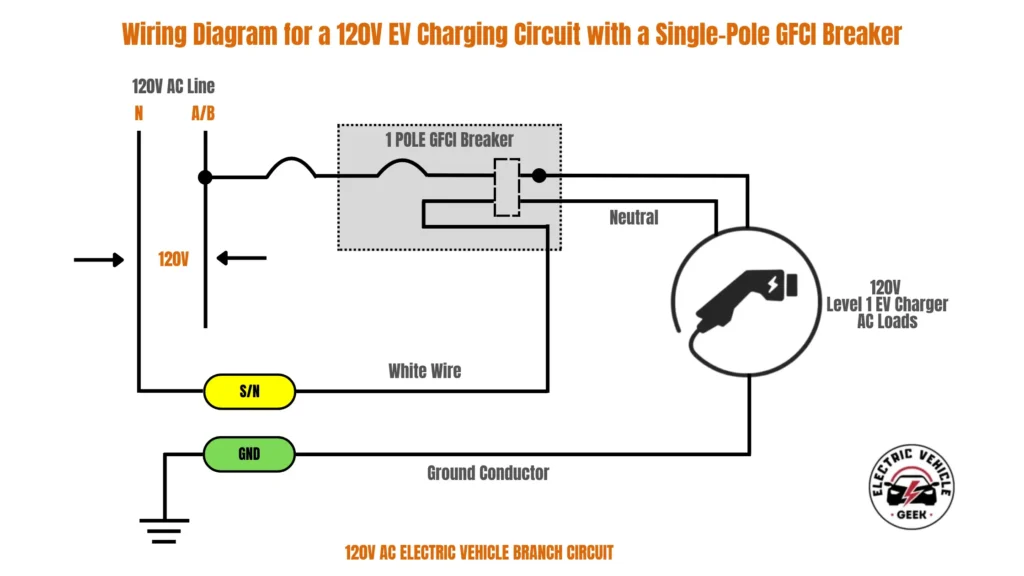

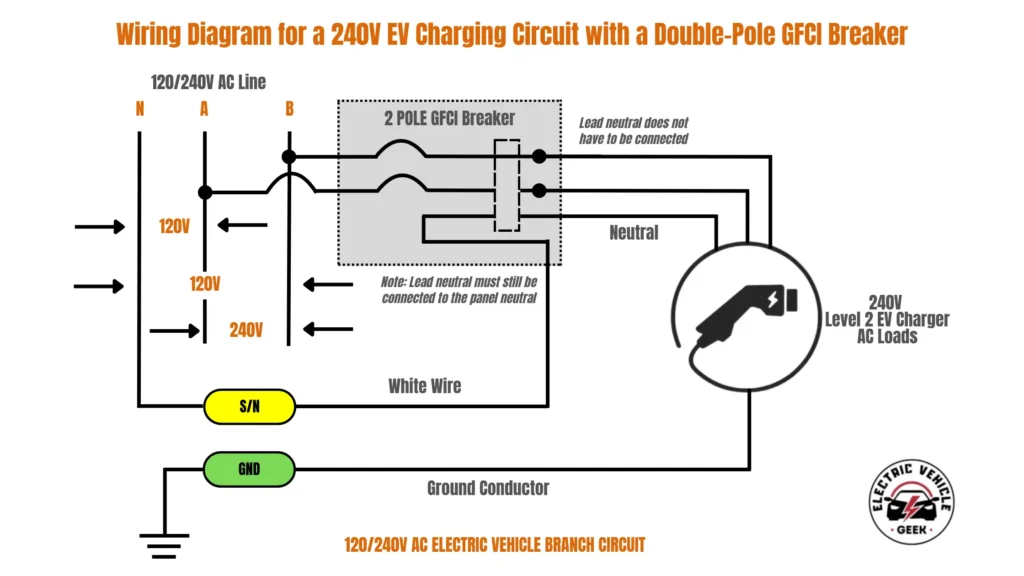

Typically, single-pole GFCI breakers are used for 120V Level 1 EV chargers, while double-pole GFCI breakers are common for 240V Level 2 EV charger installations.

The diagram below shows the wiring difference between Level 1 and Level 2 EV charger circuits.

Level 1 EV chargers operate on a 120V circuit protected by a single-pole GFCI breaker, which monitors one hot wire and the neutral.

This breaker interrupts the hot conductor if a ground fault occurs, ensuring user safety. The GFCI provides both the protected hot and neutral connections to the charger, while a dedicated ground wire offers a safe path for fault current.

Level 2 EV chargers use a double-pole GFCI breaker that protects both hot wires on a 240V circuit, disconnecting them simultaneously for enhanced safety.

The double-pole GFCI breaker connects to two hot legs and a neutral from the main panel, with a neutral pigtail ensuring proper GFCI function. Depending on the charger’s design, the neutral connection may be optional. A dedicated ground wire runs separately, providing a safe fault current path.

Additionally, many EV chargers require specialized GFCI breakers, such as Type A, Type B, Type EV, or Special-Purpose models, chosen based on their fault leakage thresholds and whether they include built-in DC leakage detection (CCID) protection.

For example, Type B GFCI breakers detect AC and pulsating DC leakage and are suitable for most residential EV chargers without built-in GFCI protection. Type EV and Special-Purpose breakers provide enhanced detection of both AC and DC leakage currents with higher trip thresholds, making them ideal for faster Level 2 or commercial EV chargers, or for EV chargers that already include built-in GFCI protection, balancing sensitivity with reduced nuisance tripping.

Always refer to your EV charger’s specs and local codes, and consult a certified installer or licensed electrician to ensure the correct breaker type and safe installation.

Proper Sizing, Compatibility, and Wiring

Choose a properly sized GFCI breaker and matching wire gauge based on your EV charger’s load and distance, install it in the main or subpanel, and always follow manufacturer instructions and NEC codes to ensure safety and performance.

| EV Charger Rating (Continuous Loads) | GFCI Breaker Size | Hot Wire Wire Gauge (AWG) | Hot Wire Wire Size (mm²) |

|---|---|---|---|

| 12 A | 15 A | 14 AWG | 2.08 mm² |

| 16 A | 20 A | 12 AWG | 3.31 mm² |

| 20 A | 25 A | 10 AWG | 5.26 mm² |

| 24 A | 30 A | 10 AWG | 5.26 mm² |

| 28 A | 35 A | 8 AWG | 8.37 mm² |

| 32 A | 40 A | 8 AWG | 8.37 mm² |

| 36 A | 45 A | 6 AWG | 13.3 mm² |

| 40 A | 50 A | 6 AWG | 13.3 mm² |

| 48 A | 60 A | 4 AWG | 21.2 mm² |

| 56 A | 70 A | 4 AWG | 21.2 mm² |

| 64 A | 80 A | 3 AWG | 26.7 mm² |

| 72 A | 90 A | 2 AWG | 33.6 mm² |

| 80 A | 100 A | 2 AWG | 33.6 mm² |

The GFCI breaker’s amperage rating is determined by the EV charger’s maximum continuous load, typically specified in the charger’s manual or nameplate. According to the National Electrical Code (NEC) Article 625, the breaker must be rated at least 125% of the charger’s continuous current to ensure safe operation and prevent nuisance trips.

Wire size is determined by the breaker’s amperage rating and the length of the run between the panel and the charger. NEC Table 310.16 provides ampacity ratings for conductors, while NEC Sections 210.19 and 310.15 cover sizing based on load and voltage drop considerations.

We recommend copper conductors in EV charger installations for their superior conductivity and durability, which prevent overheating, voltage drop, and reduce GFCI nuisance tripping. Proper wire gauge is essential for preventing overheating and voltage drop, which are critical for the charger’s performance and safety. Equally important, proper EV charger grounding provides a crucial safety path to prevent electric shock in the event of an electrical fault.

GFCI Breaker Testing and Maintenance

Regular testing and maintenance of GFCI (Ground Fault Circuit Interrupter) breakers is a critical safety practice for any home EV charging setup.

A GFCI breaker is a life-safety device that protects people, not just wiring. Unlike a standard dedicated EV charger circuit breaker, which protects wiring and equipment from overloads or short circuits, a GFCI continuously monitors the balance of current between the hot (line) and neutral conductors, and trips within milliseconds if even 4–6 mA leaks to ground.

In EV charging, where high voltage, outdoor conditions, and frequent human interaction increase risk, this rapid response can mean the difference between a harmless trip and a fatal shock.

Simple GFCI Breakers Testing

The simplest and most effective way for homeowners to test a GFCI breaker is by using its built-in TEST and RESET buttons. This process simulates a ground fault in a safe and controlled way:

- Preparation: Plug the EV charger into the dedicated electric vehicle branch circuit protected by the dedicated GFCI breaker’s circuit and switch it on.

- Test: Locate the GFCI breaker in the panel and press the TEST button.

- Verify: If functioning properly, the breaker will trip immediately, cutting power to the circuit. The plugged-in device should turn off.

- Reset: Press the RESET button on the breaker to restore power. The device should turn back on.

If the breaker fails to trip during testing, it is not providing proper protection and should be replaced without delay.

Advanced GFCI Testing

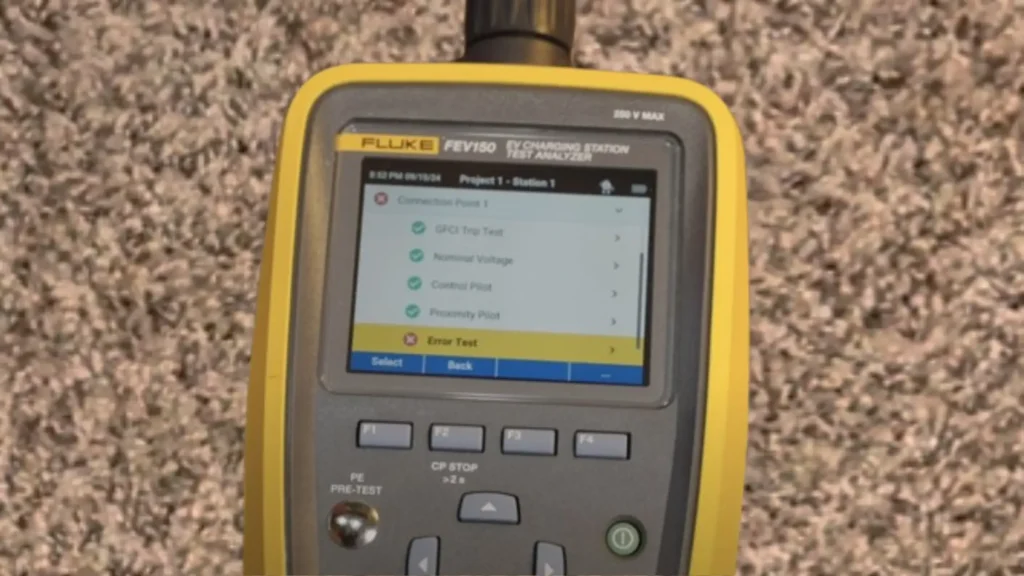

As EVSE (Electric Vehicle Supply Equipment) specialists, in our EV charger test bench, we go beyond simple functional checks. For EV charger GFCI tests, we rely on precision instruments such as the Fluke FEV150 EV Charging Station Analyzer.

Fluke FEV150 EV Charging Station Analyzer

This professional-grade tool allows us to simulate a variety of fault conditions and confirm that GFCI protection meets strict safety standards.

Using the FEV150, we can:

- Verify quick-trip GFCI responses (30 mA trip with a maximum trip time of 0.56 seconds; test current 0–10%).

- Perform troubleshooting tests for 6 mA and 20 mA GFCIs, confirming no nuisance tripping within the -10% to 0% current range.

- Validate trip performance at 10 mA (trip time limit: 2.69 s, test current 0–10%).

- Confirm compliance across a wide voltage range (100–253 VAC, 45–66 Hz).

These tests are critical for EVSE installations because EV chargers often incorporate additional GFCI protection (such as 6 mA leakage detection), and proper coordination between the breaker and EVSE prevents nuisance tripping while ensuring safety.

How Often Should You Test?

We recommend monthly testing for EV charging dedicated GFCI breakers. After power outages or electrical surges, testing becomes even more important. Some manufacturers may specify different intervals, so it’s wise to review your breaker’s documentation. Routine testing identifies failures early, before they can pose a hazard.

Understanding Nuisance EV Charger GFCI Breaker Tripping

Over time, you may encounter EV Charger GFCI breaker nuisance tripping, where a breaker trips without an actual ground fault.

Common causes include:

- Cumulative leakage current: Multiple EV charging accessories connected to the electric vehicle charging branch circuit with minor leakage can add up and exceed the breaker’s sensitivity.

- Improper wiring: Incorrect EV charger installation can mimic a fault condition.

- Faulty appliances: Minor internal leakage in EV charging systems can trip a GFCI without posing an immediate danger.

- Aging breakers: Mechanical wear can reduce reliability and cause false trips.

If your GFCI breaker trips frequently without a clear cause, consult a qualified electrician or certified EV charger installer. Persistent tripping can indicate a wiring or equipment issue that needs professional attention.

Related Guides

- Electric Vehicle Charger Circuit Breaker Selection Guide

- NEMA 14-50 GFCI Outlet for EV Charging

- EV Charger Surge Protection Guide

- EV Charger Earthing Guide

- EV Charger Circuit Breaker Keeps Tripping

Frequently Asked Questions

Do EV chargers need GFCI protection?

Yes, most EV chargers require GFCI protection, but the specifics depend on the installation and local code. According to NEC 2023, all plug-in chargers (Level 1 and 2) must have GFCI-protected outlets, while hardwired chargers generally rely on built-in ground-fault protection unless installed in locations requiring external protection (e.g., outdoors).

Are SPGFCIs and “Type EV” breakers the same?

No, they are not the same, but they refer to similar technology.

SPGFCI is the official term used in the 2023 National Electrical Code (NEC) for devices designed to handle circuits over 150V with higher trip thresholds to accommodate smooth DC leakage currents found in EV chargers.

Type EV is an industry term used more informally to describe breakers designed specifically for electric vehicle charging. While not formally defined by the NEC, Type EV breakers use the same underlying technology as SPGFCIs and align with international Type B residual current device (RCD) standards

Why Does EV Charging Cause GFCI Tripping?

GFCI tripping during EV charging is commonly caused by inherent leakage currents from charger electronics, transient grid voltage fluctuations, compromised wiring integrity, moisture intrusion, internal charger faults, or occasional vehicle charging system issues. These conditions can trigger false ground fault detections, resulting in nuisance trips even when the system operates safely.

Why Do Standard GFCIs Cause Nuisance Tripping with EV Chargers?

Standard GFCIs have a low trip threshold (4–6 mA) that can conflict with the higher internal ground-fault protection of EV chargers (typically 20 mA), causing nuisance trips. To resolve this, the upcoming NEC 2026 will likely mandate Special-Purpose GFCIs (SPGFCIs) designed for EVs, offering reliable protection with fewer false trips.

How Can I Prevent GFCI Nuisance Tripping During EV Charging?

Use a Special-Purpose GFCI (SPGFCI) or Type EV breaker designed for EV chargers, as they handle DC leakage better than standard GFCIs. Prefer EV chargers with built-in safety features such as GFCI protection. Use properly sized wiring and quality outlets, opt for hardwired installations when possible, keep connections dry, and test breakers regularly. For persistent issues, consult a licensed electrician.

What Is a GFCI Receptacle for EV Chargers?

A GFCI receptacle for EV Chargers is a specialized electrical outlet with built-in ground-fault protection, often identified by a reset button on its face. It quickly shuts off power if it detects an electrical imbalance or leakage in an electric vehicle’s branch circuit, protecting users from shock.

James Ndungu is a certified EV charger installer with over five years of experience in EVSE selection, permitting, and installation. He holds advanced credentials, including certification from the Electric Vehicle Infrastructure Training Program (EVITP) and specialized training in EV charging equipment and installation, as well as diplomas in EV Technology and Engineering Fundamentals of EVs. Since 2021, James has tested dozens of EV chargers and accessories, sharing expert insights into the latest EV charging technologies.