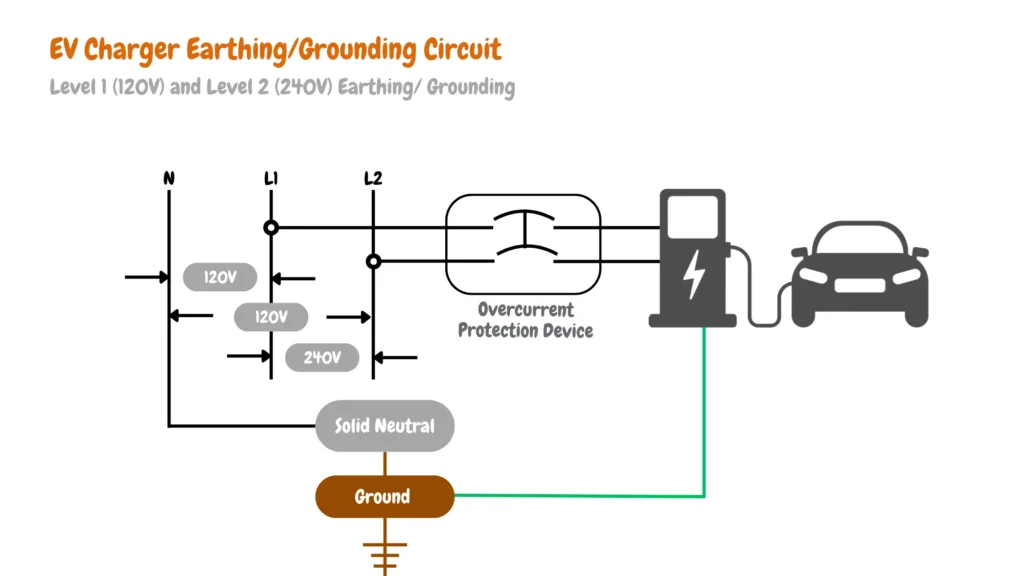

EV charger earthing, or grounding, connects the electric vehicle charging circuit to the ground to ensure safety and proper functionality. This involves installing a grounding conductor that links the electric vehicle’s branch circuit to the earth’s conductive surface. The connection uses grounding electrodes, conductive wires, and grounding conductors.

Electric vehicle branch circuit grounding is typically achieved using a thick copper grounding conductor. This wire connects all exposed metallic parts of the EV charger’s branch circuit to a grounding electrode, such as an earth rod or ground plate buried in moist soil. As shown in the grounding diagrams below, this applies to both 120V/240V split-phase single-phase systems used in North American residential wiring, as well as three-phase EV charger installations used in commercial EV charger installations.

Table of Contents

- Single-Phased EV Charger Circuit Grounding (USA & Canada)

- Three-Phase EV Charger Circuit Grounding

- Does an EV Charger Need to Be Grounded?

- Critical Points Requiring Grounding for EV Chargers

- EV Chargers Grounding/Earthing Components.

- EV Charger Earthing Methods and Types

- Protective Multiple Earth (PME) in EV Charger Installation

- NEC Specifications of Grounding

- Conclusions.

Single-Phased EV Charger Circuit Grounding (USA & Canada)

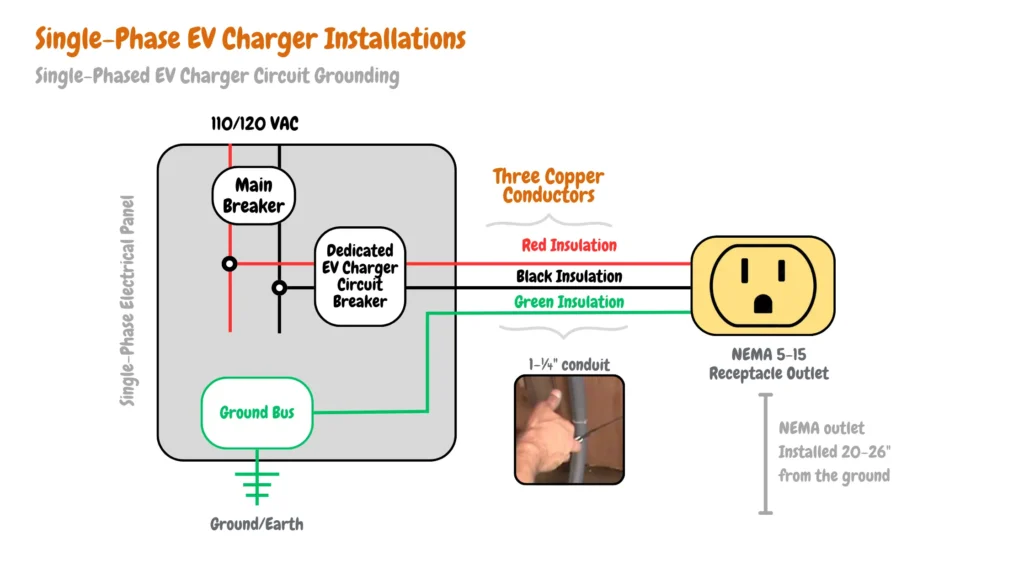

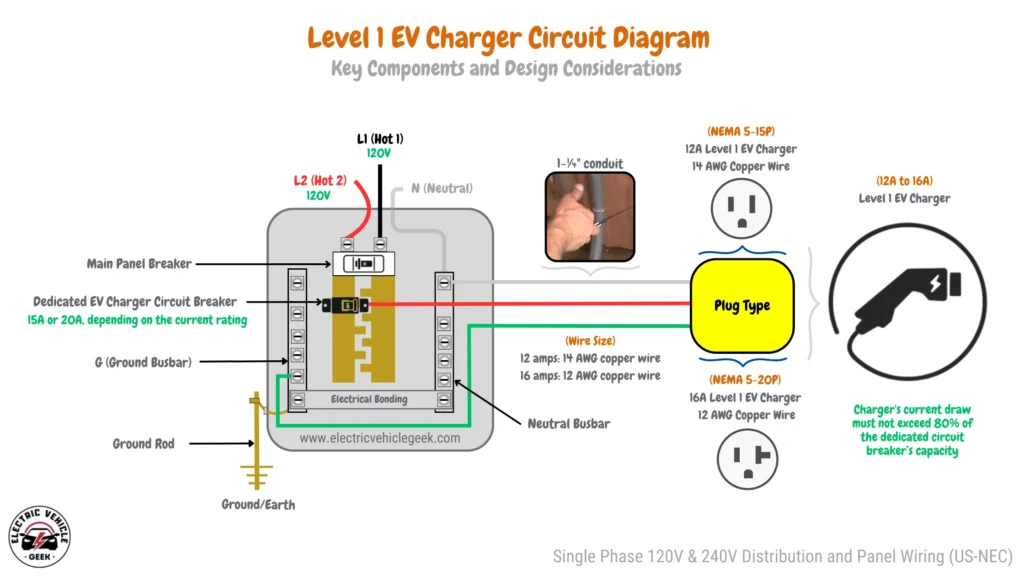

The diagram below demonstrates how a single-phase EV Level 1 charger installation is grounded. It shows the connection between the electrical system and the earth using grounding electrodes and conductors, ensuring a safe and reliable setup.

Level 1 EV Charger Grounding

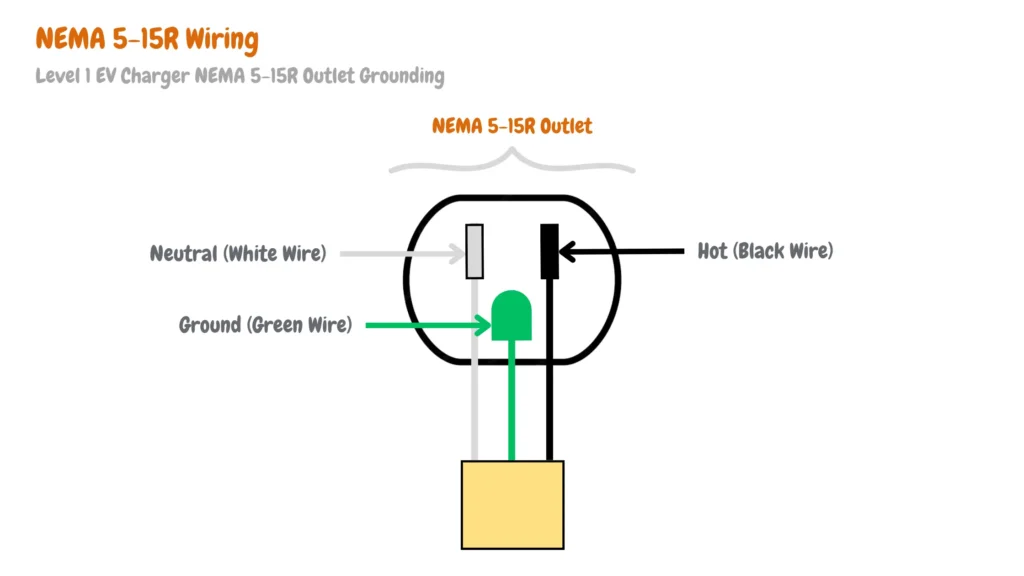

Level 1 EV chargers utilize a standard NEMA 5-15R or NEMA 5-20 outlet, typically found on a 120-volt circuit. Proper grounding involves connecting the outlet’s grounding conductor to the grounding system of the electrical panel, as shown in the wiring diagrams below:

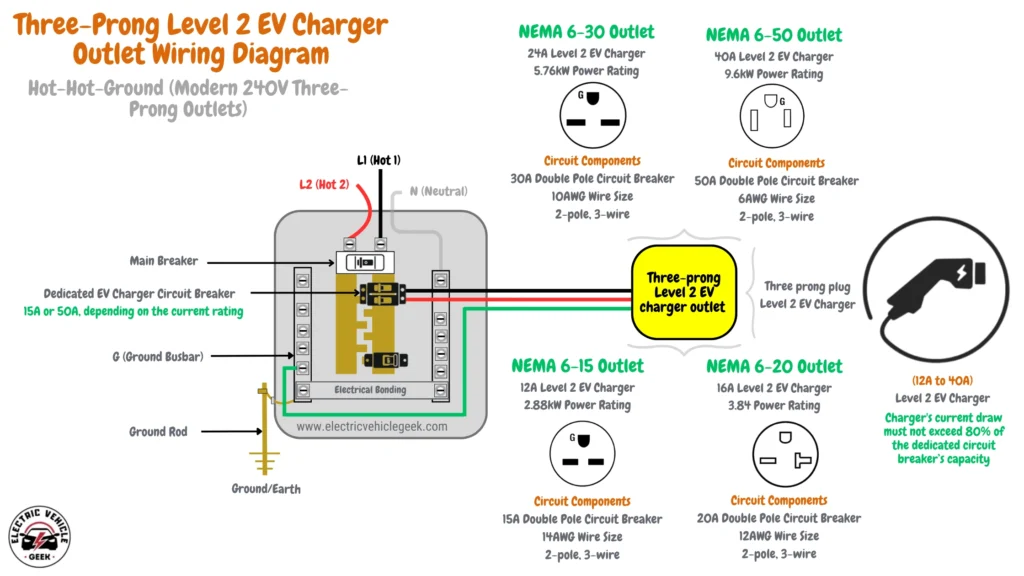

Level 2 EV Charger Outlet Grounding

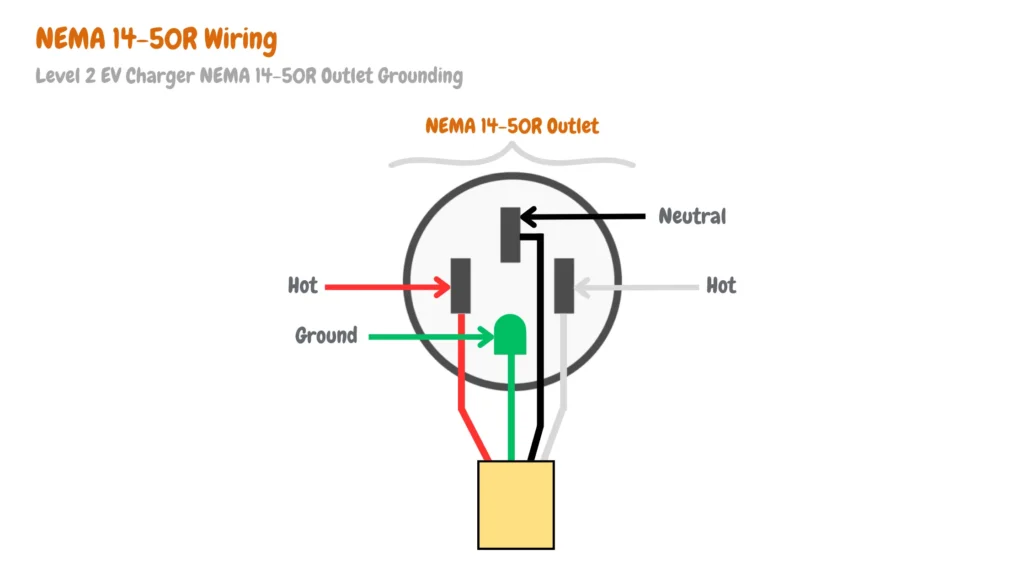

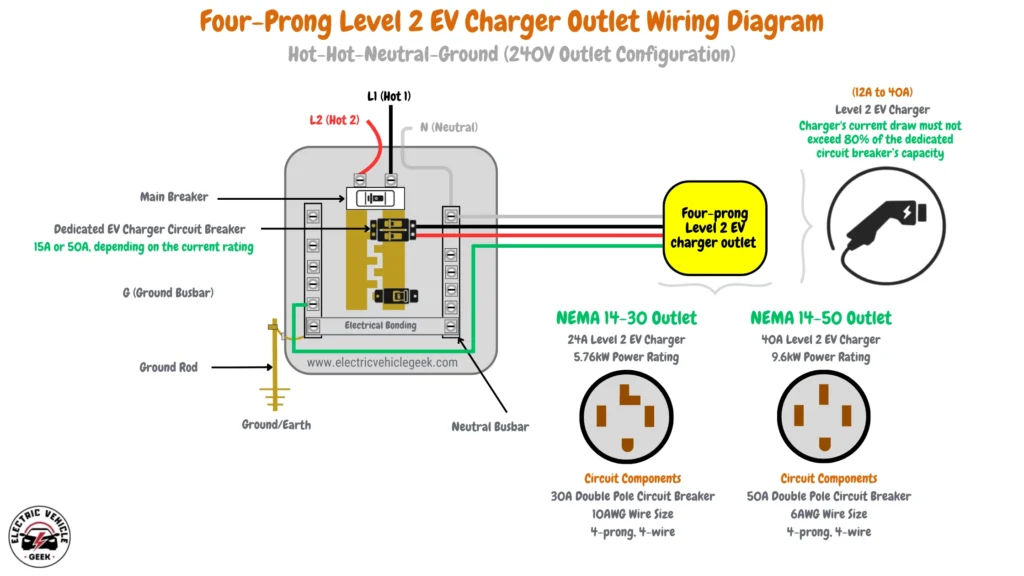

Level 2 EV chargers commonly use a NEMA 14-50R outlet, which operates on a 240-volt circuit. Proper grounding involves securely connecting the outlet’s grounding terminal to the equipment grounding conductor (EGC), which must be bonded to the main grounding system at the electrical panel.

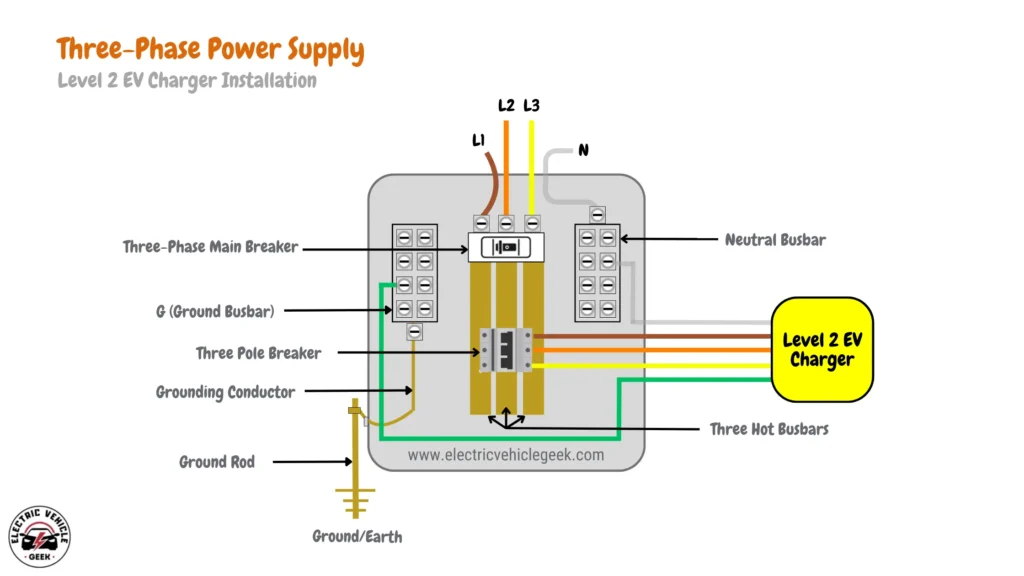

Three-Phase EV Charger Circuit Grounding

The diagram below illustrates the grounding process for a three-phase Level 2 EV charger. It details the connections required to safely ground three-phase EV charger installations, ensuring stability and safety in high-power installations.

Check out our guide on Three-Phase EV Charger Installation – NEC – US for detailed installation instructions and NEC compliance tips.

Does an EV Charger Need to Be Grounded?

When metallic parts of your electric vehicle branch circuit, like outlets and electrical panels, come into contact with a live wire (EV charger leakage fault/ EV charger ground fault) —potentially due to EV charger installation failures or cable insulation breakdown—the metal can become charged. This charge accumulates static electricity. If you touch these charged metallic parts while connecting your EV charger plug or during vehicle charging, you risk electric shock.

To prevent EV charger leakage faults and ground faults, the electric vehicle branch circuit must be properly grounded, allowing any electrical charge to dissipate safely into the earth in the event of a fault, but they are not intended for continuous current flow.

Additional methods for EV charger leakage protection include using devices like ground fault circuit interrupters (GFCIs) or residual current devices (RCDs). These devices monitor for current imbalances and automatically cut off the power supply when leakage is detected, effectively preventing electrical hazards.

Critical Points Requiring Grounding for EV Chargers

Before installing an EV charger, it is essential to identify and properly ground all components that could present a safety hazard in the event of a fault. Grounding not only ensures user protection but also guarantees compliance with NEC 250.110 and other applicable standards.

Exposed Metallic Enclosures and Casings

All conductive enclosures and metallic casings associated with the EV charging branch circuit must be bonded to the system grounding path. This includes:

NEMA EV Charger Outlets

For EV chargers using plug-and-socket configurations (e.g., NEMA 5-15R for Level 1 and NEMA 14-50R for Level 2), the grounding pin on both the plug and receptacle must be securely and continuously connected to the grounding system. This connection provides a direct path for any fault current and must be verified during installation and inspection.

For detailed grounding procedures, refer to our NEMA Outlet Installation Guide for practical tips and code-compliant grounding methods.

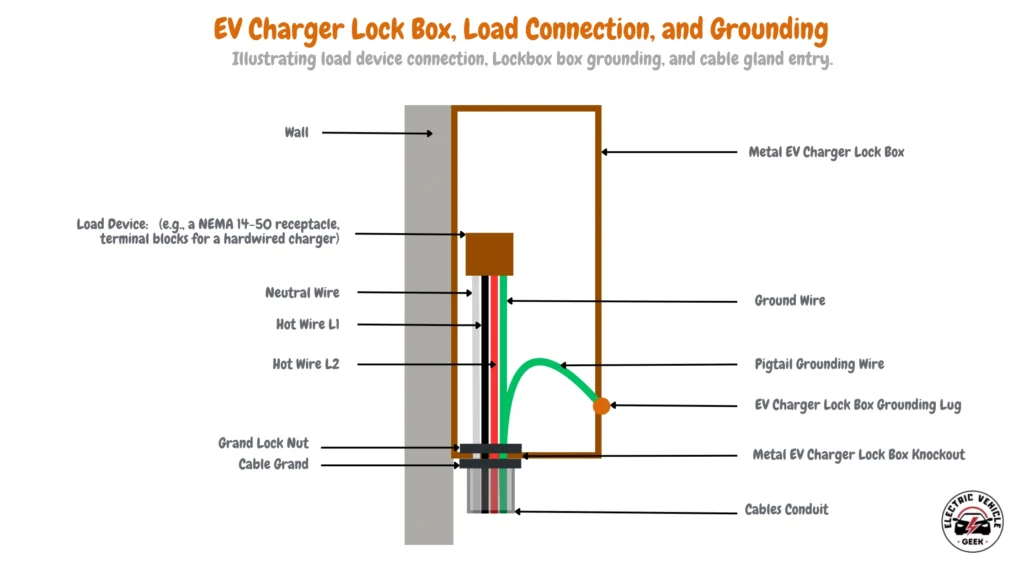

Metal EV Charger Lock Boxes

To ground a metal EV charger lock box, first, install the lock box on the wall and route the hot (L1, L2), neutral, and ground wires to the appropriate terminals on the load device (e.g., NEMA 14-50 receptacle or terminal blocks). Connect the ground wire to the grounding lug inside the box, using a pigtail grounding wire for proper bonding as shown in the diagram below:

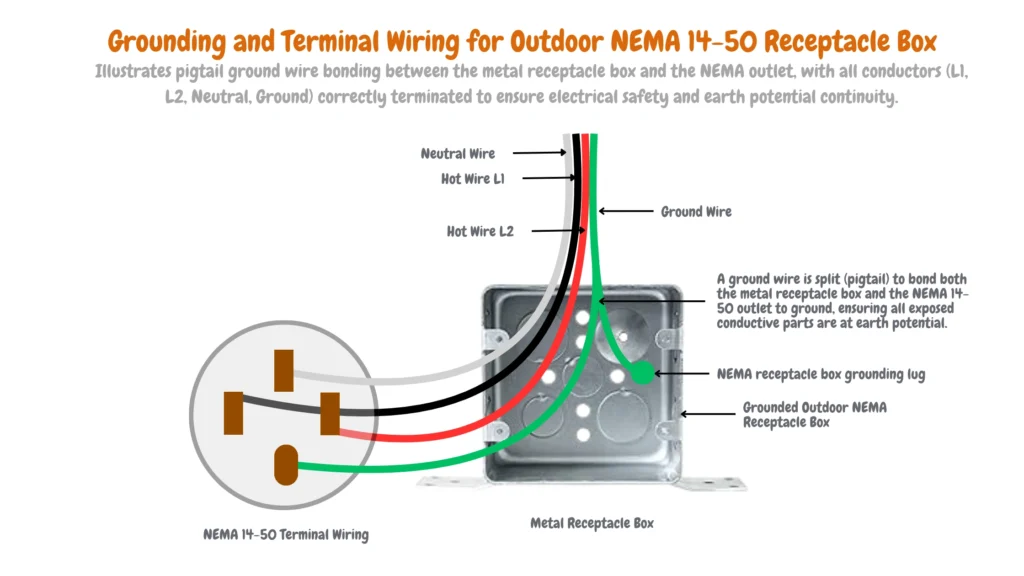

Metallic Junction Boxes & Receptacle Boxes

Proper grounding of metallic junction and receptacle boxes is essential for safety in EV charger installations. The ground wire must be securely connected to the grounding terminal inside the box, and the box itself must be bonded to the grounding system using a grounding screw or lug.

For multiple connections, a grounding jumper wire may be required.

Metal Conduits (e.g., EMT, RMC)

Ground metal conduits like EMT and RMC by bonding them to the grounding system using approved connectors at both ends. This provides a path for fault currents to safely reach the ground.

Iron-Clad Switches

Ground iron-clad switches by connecting the grounding wire to the switch’s grounding terminal, ensuring fault currents are safely directed to the ground.

Metal EV Charger Pedestals

Metal EV charger pedestals must be grounded to prevent electric shock and ensure compliance with safety standards. A grounding conductor must be securely bonded to the metal structure of the pedestal and connected to the system’s main earthing point (MET).

In PME systems, the pedestal’s grounding must also ensure continuity with the PEN conductor to maintain a low-resistance fault path.

EV Charger Pedestal Related Guides

- EV Charger Pedestals 101

- Plug-In EV Charger Pedestal Installation Guide

- Hardwired EV Charger Pedestal Installation Guide

Electrical Distribution Panels

Ground electrical distribution panels by connecting the grounding conductor to the panel’s grounding bus. This directs fault currents safely to earth and ensures compliance with safety standards.

Renewable Energy and Grid-Tied Charger Installations

In hybrid systems using both renewable energy (e.g., solar) and utility power, it is critical to ground all exposed metallic components of the energy system. This includes:

Transformer Frames

To ground transformer frames, connect the grounding conductor to the grounding lug on the frame. This provides a secure path for fault currents to safely flow to Earth, protecting both the equipment and users.

Metallic Inverter Housings

For metallic inverter housings, attach the grounding conductor to the grounding terminal on the housing. This ensures the inverter’s metal parts are properly bonded to the grounding system, safeguarding against electrical shock hazards.

Combiner Boxes and Disconnect Enclosures

In combiner boxes and disconnect enclosures, connect the grounding conductor to the grounding lug or terminal. This step ensures that any fault current is safely directed to the ground, preventing electrical hazards and ensuring system safety.

EV Chargers Grounding/Earthing Components.

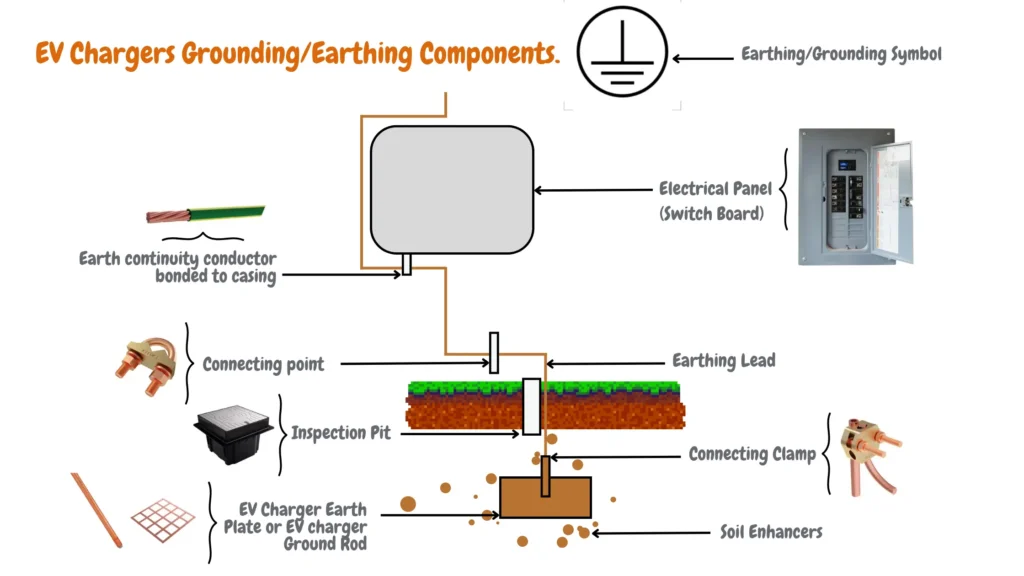

Components used for grounding/earthing EV charger installations include:

- EV charger electrode conductor.

- EV charger earthing/grounding conductor.

- EV charger earth rod or plate.

The diagram below illustrates the essential grounding components for a safe EV charger installation. It illustrates the electrical path connecting the main service panel to the EV charger’s grounding electrode (earth rod or plate). The diagram also identifies the grounding conductor and any additional electrodes contributing to the grounding system.

EV Charger Electrode Conductor

An EV charger electrode conductor is part of the EV charger grounding system that interconnects all the parts of the metallic parts of the electric vehicle branch circuit such as electrical panels, subpanels, junction boxes, outlets, and the EV charger.

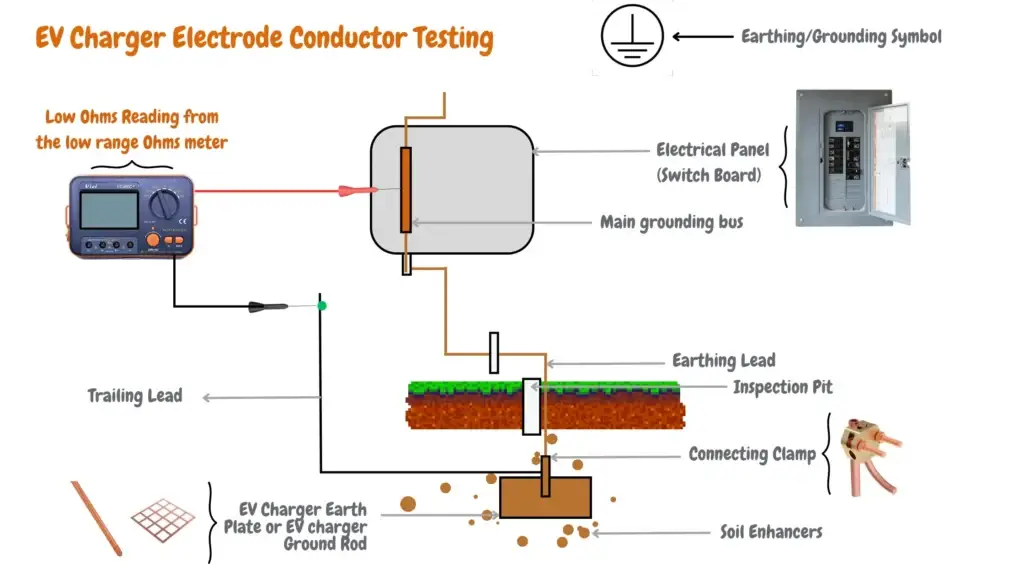

To test the EV charger electrode connecter after EV charger installation we use the Vici VC480C+ LCD Digital Micro-ohm Meter since the EV charger electrode conductor resistance should be very low to make sure the components of the electric vehicle branch circuit grounding are at the same potential as the ground or earth to prevent the electric vehicle branch circuit from causing EV charger ground fault to incase of insulation faults.

We recommend purchasing the Vici VC480C+ LCD Digital Micro-ohm Meter for frequent monitoring of your electric vehicle branch circuit electrode conductor resistance or continuity to maintain and troubleshoot your EV charger installation, especially in case you experience ground fault errors being displayed on your EV charger.

Your standard digital multimeter can’t measure the resistance or continuity of your EV charger electrode conductor. For accurate results, use the Vici VC480C+ LCD Digital Micro-ohm Meter, which ranges from 0.1µΩ to 2000Ω. Unlike household multimeters like the AstroAI Multimeter Tester, the VC480C+ meets IEEE standards, ensuring the earth wire’s resistance remains below 1Ω. This compliance is critical for maintaining the safety and functionality of your EV charger installation.

After installation, we recommend keeping a record of the resistance or continuity readings of your EV charger electrode conductor using the Vici VC480C+ LCD Digital Micro-ohm Meter and during maintenance, troubleshooting, or repairs and identify any significant resistance increases that could indicate loose connections or deterioration to prevent shocks.

When EV charger circuit breakers trip due to an EV charger earth leakage fault or EV charger ground fault, the culprit can be the EV charger electrode conductor whose ground fault and the leakage current exceeds the set limit, if you have an EV charger GFCI circuit breaker, it will trip to prevent potential electrical shock hazards

When choosing the right EV charger grounding cable, the electric vehicle branch circuit electrode conductor size with be dependent on the electric vehicle branch circuit cable/wire size.

Size of EV Charger Electrode Conductor

According to IEC Regulation, the Earth Continuity Conductor should have a cross-sectional area of at least half of the thickest wire used in the installation, with a minimum of 6 mm². For Level 1 and Level 2 EV chargers, a 6 mm² is recommended.

EV Charger Earthing Lead/Grounding Lead Conductor

The point that connects the EV charger electrode conductor and the EV charger earth plate, EV charger earth pipe, EV charger earth rod, EV charger waterman earthing, or the EV charger strip earthing depending on your EV charger grounding or earthing method is known as the EV charger earthing lead/grounding lead conductor

The EV charger earthing lead/grounding lead conductor is the final part of the EV charger earthing system connected to the EV charger electrode conductor, and the underground EV charger earthing system, depending on your EV charger installation method your EV charger earthing/grounding Electrode might be an earth plate, earth pipe, earth rod, waterman or strip earthing.

Not only does the EV charger earthing lead/grounding lead conductor connect the EV charger electrode conductor, and the underground EV charger earthing system, but we also use its connection points to maintain and repair an EV charger earth leakage and faults caused by the EV charger electrode conductor insulation faults as shown in the illustrative image below:

For earth leakage and fault testing using a low-range ohms meter, we recommend the Vici VC480C+ LCD Digital Micro-ohm Meter. Connect the red probe to the main grounding bus in the EV charger’s electrical panel.

The crucial step is ensuring a good connection on the EV charger earth leads using the black probe. If the lead isn’t directly accessible, a trailing lead (as detailed in our Guide to Testing EV Charger Earth Leakage and Faults) can be employed to reach the grounding point.

As shown in the image above, the EV charger earthing lead/grounding lead conductor should be smaller in size compared to the EV charger electrode conductor and should be installed straight to the ground towards the EV charger earthing lead/grounding lead conductor.

For EV charger installations such as Level 2 and Level 3 EV chargers, we recommend the use of a copper strip as the EV charger earthing lead/grounding lead conductor, while for Level 1 installations you can use a copper wire, we recommend a copper strip for high current EV charger installations due to their wider ware that can handle high EV charger fault currents compared to the use of a copper wire.

Size of EV Charger Earthing/Grounding Conductor

The size of an EV charger grounding conductor is typically based on the breaker size, as indicated in NEC Table 250.122. This ensures they can handle fault currents without damage.

The table below will help you select the appropriate size for the grounding conductor in your EV charger installation, based on the charger rating (continuous loads), dedicated EV charger circuit breaker size (according to the 20/80 rule), and conductor material (copper or aluminum).

| EV Charger Rating (Continuous Loads) | EV Charger Dedicated Breaker Size (20/80 Rule) | Grounding Conductor (Copper) | Grounding Conductor (Aluminum) |

|---|---|---|---|

| 12 Amp | 15 Amp | 14 AWG | 12 AWG |

| 16 Amp | 20 Amp | 12 AWG | 10 AWG |

| 20 Amp | 25 Amp | 10 AWG | 8 AWG |

| 24 Amp | 30 Amp | 10 AWG | 8 AWG |

| 28 Amp | 35 Amp | 10 AWG | 8 AWG |

| 32 Amp | 40 Amp | 10 AWG | 8 AWG |

| 36 Amp | 45 Amp | 10 AWG | 8 AWG |

| 40 Amp | 50 Amp | 10 AWG | 8 AWG |

| 48 Amp | 60 Amp | 10 AWG | 8 AWG |

| 56 Amp | 70 Amp | 8 AWG | 6 AWG |

| 64 Amp | 80 Amp | 8 AWG | 6 AWG |

| 72 Amp | 90 Amp | 8 AWG | 6 AWG |

| 80 Amp | 100 Amp | 8 AWG | 6 AWG |

EV Charger Earthing/Grounding Electrode

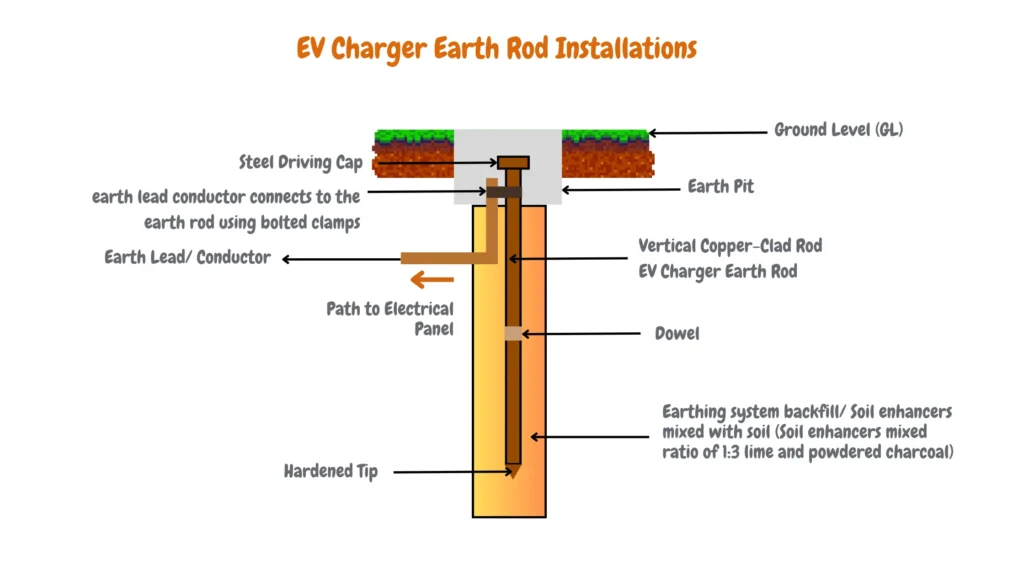

An EV charger earthing/grounding electrode is the final component of the EV charger earthing or grounding system, although EV charger earth rods and EV charger earth plates are the common EV charger earthing/grounding electrodes other EV charger earthing/grounding electrodes can be used in EV charger installation such as EV charger earth pipe, waterman or strip earthing depending on e.g. soil type, moisture degradation/corrosion of the earth rod over time.

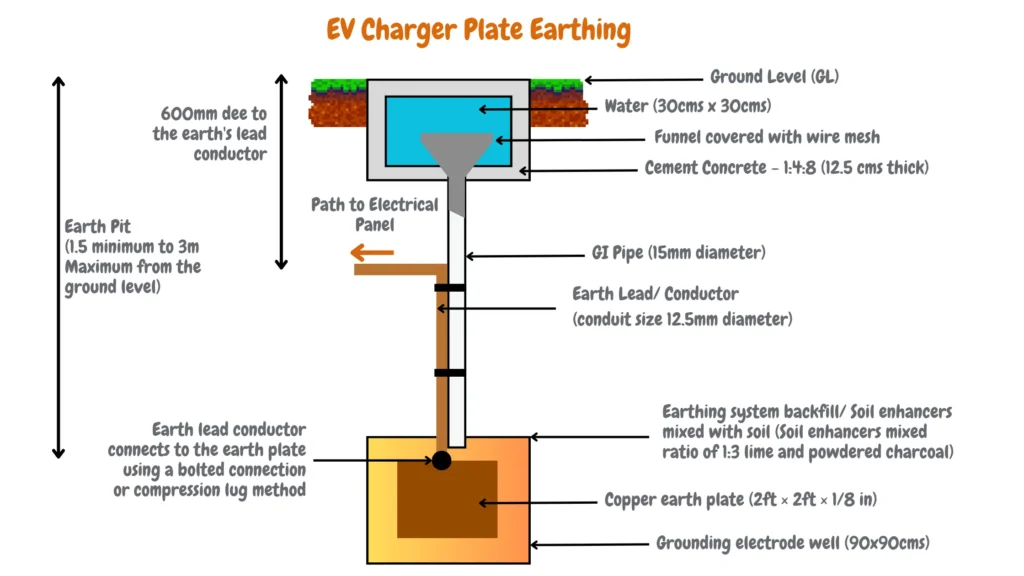

One thing about the EV charger earthing/grounding electrodes no matter what method or type you use on your EV charger installation, we recommend the use of soil enhancers (mixture of charcoal and lime -ratio of 1:3), to improve EV charger earthing/grounding electrode effectiveness in dissipating electrical current into the earth, soil enhancers help lowers soil resistivity, reduced grounding resistance, and help increase the conductivity of the soil including dry, sandy, or rocky soil surrounding the grounding electrode over time.

Size of EV Charger Earthing/Grounding Electrode

When installing an earthing system, using copper as the electrode material is highly recommended due to its superior conductivity and corrosion resistance. A copper electrode should measure 2 feet by 2 feet with a thickness of 1/8 inch (600 mm × 600 mm × 3 mm). It is advisable to bury the electrode in moist soil. If moist soil is unavailable, water can be added to the GI (Galvanized Iron) pipe to create the necessary moisture conditions. To further enhance conductivity, salt, and charcoal are added to the earthing pit.

For the EV Charger earth rod, a solid copper rod is recommended. It should be 8 feet (≈2.5 meters) in height and 1/2 inch (12 mm) in diameter. The earth electrode should be installed vertically underground and surrounded by a 1-foot (30 cm) layer of a powdered charcoal and lime mixture in a 1:3 ratio (1 kg of salt to 3 kg of charcoal). This practice helps maintain moisture around the earth’s plate and ensures better continuity in the grounding system.

EV Charger Earthing Methods and Types

There are two common EV charger earthing methods used in EV charger installations, the use of an EV charger earth plate, or an EV charger earth rod, although other three EV charger methods exist such as the use of EV charger earth pipe, Ev charger waterman or strip earthing.

EV Charger Earth Plate

EV charger earth plates are commonly used in permanent, hardwired EV charger installations. These plates are typically installed by EV charger installers at a depth of 1.5 to 3 meters below ground. We generally use a 2 ft × 2 ft × 1/8 in copper earth plate for these installations, as shown in the illustrative image below.

EV Charger Earth Rod

The second most popular EV charging earthing or grounding method is the use of a copper-clad rod EV charger earth rod, EV charger earth rods are common with DIY EV charger installers (which mostly consist of plug-in EV charger installers), but can also be used in hardwired EV charger installations.

Depending on the soil type, and moisture degradation/corrosion of the earth rod over time the size of the copper-clad rod EV charger earth rod should be a minimum of 3/8in diameter and f4ft in length, however, we recommend 1.5in in diameter and 9ft in length for single home EV charger installation using level 2 and Level 1 EV chargers. In rocky and dry soils a greater dimension copper-clad rod EV charger earth rod is required.

After installation of your EV charger earth rod, use the Vici VC480C+ LCD Digital Micro-ohm Meter to measure the ground resistance or continuity, and if it’s greater than 25 ohms you should install a supplementary copper-clad rod EV charger earth rod 6ft apart.

Protective Multiple Earth (PME) in EV Charger Installation

Protective Multiple Earthing (PME) connects the electrical system to the ground at multiple points, both at the supply and within the EV charger source, providing low-resistance paths to safely divert excess current into the earth.

This setup is especially beneficial in the event of an Open-Circuit PEN Conductor fault, where the neutral wire breaks. In such cases, the fault current returns to the supply through parallel paths via the earth, creating a low-resistance circuit.

This allows protective devices, such as fuses or breakers, to trip quickly by facilitating high fault currents and cutting off power to prevent shocks, fires, or equipment damage. PME is essential for maintaining safety and reliability in EV charger installations.

NEC Specifications of Grounding

The National Electrical Code (NEC Article 250) outlines various specifications for electrical grounding systems to ensure safety:

- Grounding Electrode System: Every electrical system needs a grounding electrode system, which consists of one or more electrodes like rods, plates, or pipes buried in the earth.

- Minimum Requirements: At least two grounding electrodes are required unless a single electrode achieves resistance to earth below 25 ohms.

- Electrode Installation: Electrodes must be straight down for at least 2.44 meters and be free from non-conductive coatings. Spacing between electrodes from different systems should be at least 1.83 meters.

- Grounding Conductor: A grounding electrode conductor connects the grounding electrode system to the grounded conductor at the service entrance.

- Bonding: The grounded conductor is bonded to the service enclosure and equipment grounding conductors to create a unified grounding path.

- Conductor Sizing: The NEC provides tables specifying the minimum size for grounding and bonding conductors based on system parameters.

Conclusions.

Grounding EV chargers is crucial for safety, compliance, and functionality. This guide covers key aspects of EV charger grounding, emphasizing adherence to National Electrical Code (NEC) standards.

- Circuit Grounding: Single-phased and three-phased EV chargers require different grounding approaches. Proper grounding ensures safety and stability.

- NEMA Outlets: Grounding for Level 1 (NEMA 5-15R) and Level 2 (NEMA 14-50R) chargers involves specific practices to meet NEC requirements and prevent electric shocks.

- Critical Grounding Points: Properly grounding the charger, circuit, and components is essential to provide a safe fault current path and protect the system.

- Components and Conductor Sizing: Correctly sized grounding components and conductors ensure effective fault current dissipation. This includes the electrode conductor, earthing lead, and grounding electrode.

- Earthing Methods: Different methods, like earth rods and plates, offer various advantages. Proper installation ensures effective grounding and reduces electric shock risks.

- NEC Compliance: Following NEC guidelines is critical for legal and safe EV charger operation. These standards protect users and equipment.

Effective EV charger grounding involves understanding charger types, installation environments, and regulatory standards. Proper grounding protects users, and equipment, and ensures long-term functionality and reliability.

James Ndungu is a certified EV charger installer with over five years of experience in EVSE selection, permitting, and installation. He holds advanced credentials, including certification from the Electric Vehicle Infrastructure Training Program (EVITP) and specialized training in EV charging equipment and installation, as well as diplomas in EV Technology and Engineering Fundamentals of EVs. Since 2021, James has tested dozens of EV chargers and accessories, sharing expert insights into the latest EV charging technologies.

Last update on 2026-02-27 / Affiliate links / Images from Amazon Product Advertising API