We have been using molded case circuit breakers in EV charging to automatically turn off electric vehicle branch circuits when excess currents flow through them to the EV charger.

Molded case circuit breakers (MCCBs) are commonly used for Level 3 EV charging installations, primarily for their robust safety features. These same features make them an ideal choice for specific home EV charger setups, particularly those demanding heavy-duty EV circuit breakers, such as outdoor EV charger installations and fast Level 2 home EV charger installations.

Table of Contents

How MCCB Design Optimizes EV Charging

What makes MCCB unique is its design and components, they include mechanical and electrical components (thermal and magnetic) that are enclosed in a molded enclosure made from plastic or porcelain.

The molding of its case is what gives the MCCB its name and can offer EV charging safety features such as environmental protections, impact resistance, tamper resistance, and improved aesthetics of the electric vehicle branch circuit.

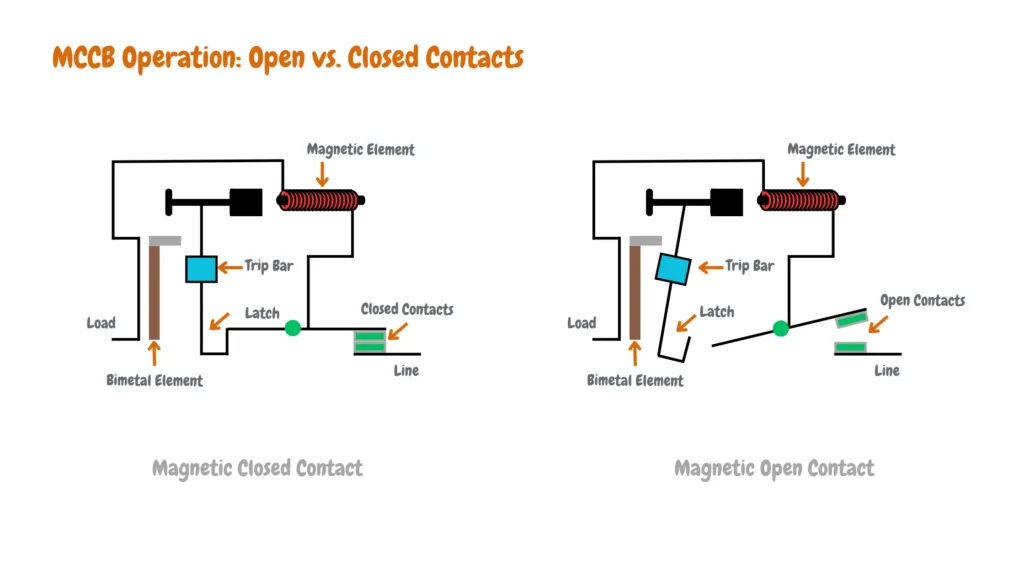

The molded case circuit breaker’s internal components include a current-carrying conductor, a tripping mechanism, an arc extinguishing chamber, and alarm switches.

When excess current from the electrical panel flows through a molded case circuit breaker connected to an EV charger, its tripping mechanism triggers the auxiliary contacts and alarm switches to open or break the electric vehicle branch circuit, this prevents damage to the EV charger from overloads and shorts, an arc chute inside the MCCB extinguishes the arc produced from breaking the electrical vehicle branch circuit.

Advanced MCCB Features for Enhanced EV Charging Safety

Modern Molded Case Circuit Breakers (MCCBs) are no longer just simple on/off switches. They’re evolving into intelligent devices that we can use in EV charging, modern MCCBs offer a suite of advanced features designed to maximize safety and minimize downtime when charging an electric vehicle:

- Ground Fault Protection: These MCCBs can detect potentially dangerous leakage currents, often caused by faulty wiring or insulation issues. This early detection helps prevent electrical fires and equipment damage.

- Arc Fault Detection: MCCBs with arc fault detection can identify the signature of hazardous electrical arcing, which can occur due to loose connections or worn components. By quickly interrupting the circuit during arcing events, these MCCBs prevent potential fires and electrical damage.

- Zone Selective Interlocking: This advanced feature coordinates the tripping sequence of multiple MCCBs in multiple EV charging installations. In the event of a fault, only the affected zone is isolated, minimizing disruption to other chargers and maximizing system uptime.

- Communicating Circuit Breakers: The future of MCCBs is connectivity. These next-generation breakers can communicate with an EV charging monitoring network, providing real-time data on circuit health and enabling remote monitoring and diagnostics. This allows for proactive maintenance and faster troubleshooting, further enhancing overall electric vehicle branch circuit reliability.

By incorporating these advanced features, MCCBs go beyond basic circuit protection, offering a comprehensive safety net for your EV charging infrastructure.

Application of MCCB in Home EV Charging

There are two common applications of MCCBs when it comes to Level 2 EV chargers home installations, they include single or multi-pole configurations in outdoor home EV charger installations and fast home EV charger installations.

MCCBs Application In Outdoor EV Charger Installations

When extending your electric vehicle (EV) branch circuit outdoors and installing the EV charger subpanel in an exposed location we normally use MCCBs. MCCBs offer superior protection compared to standard breakers, mitigating the risks associated with outdoor environments. Additionally, installing an MCCB near the point of use within the outdoor subpanel minimizes voltage drops, ensuring efficient and reliable EV charging.

Compared to common home circuit breakers MCCBs are built with a more robust and element-resistant enclosure when used with an electrical panel designed for outdoor use, they both guard your electrical vehicle branch circuit from rain, snow, dust, dirt, and other environmental factors.

Additionally, we employ MCCBs in home installations where rodent infestation is a concern, the internal components of MCCBs consist of small electrical components (thermal and magnetic0 that are protected by a molded insulating case, and the molded enclosure protects the internal components from accidental impacts, vandalism and tampering enhancing the safety of an outdoor electric vehicle branch circuit.

MCCBs Application In Fast Home EV Charger Installations

Home EV chargers are now able to deliver fast charging capabilities, for this reason, they need high-current electric vehicle branch circuits (209-240V) to be able to deliver an electrical current of 6.2 to 19.2 kilowatts to the electric vehicle, for more than 50 amps EV charger circuit breaker, we use MCCBs this is because the charger requiring more than 50 amps of current demands higher currents.

The reason we use MCCBs in fast home EV charger installations exceeding 50 amps, is because MCCBs utilize heavier-duty components like thicker contact bars and more robust arc quenching mechanisms to handle the higher fault currents (sudden surges) that can occur during fast EV charging, ordinary circuit breakers might not be ideal for handling such stresses.

Why We Use Molded Case Circuit Breakers in EV Charging

Molded case circuit breakers in EV charging offer significant advantages compared to traditional circuit breakers (MCB).

Maximizing Space for Complex EV Charging Systems

Complex EV charger installations such as multi-charger stations, solar-powered EV chargers, or bi-directional charging systems, the electrical panel can become congested with numerous components. This is where the compact design of Molded Case Circuit Breakers (MCCBs) shines.

The compact size of MCCB compared to traditional breakers (MCB) allows for optimized space utilization within the panel. This translates to easier installation, improved accessibility for maintenance, and room for additional EV charging accessories – all crucial factors in ensuring a well-functioning and future-proof charging infrastructure.

Fast EV Charging Fault Isolation.

One of the most critical features of MCCBs for EV charging applications is their lightning-fast reaction time. Unlike standard breakers that might take tens of milliseconds to trip, MCCBs can interrupt faults in as little as a few milliseconds. This rapid response is essential for protecting sensitive EV charger components and the electrical system from the damaging effects of short circuits or excessive currents.

In a split second, an MCCB can isolate the fault, minimizing equipment damage and potential safety hazards. This fast-acting capability is particularly crucial in high-power EV charging scenarios where fault currents can be significant.

Adjustable Trip Settings for Optimal EV Charging.

While most standard circuit breakers have pre-set trip current levels, some MCCBs offer an additional layer of customization. These adjustable MCCBs allow qualified electricians to fine-tune the trip settings based on the specific requirements of some smart EV chargers. This adjustability provides several benefits:

- Optimal Protection: By precisely matching the trip current to the charger’s rated current, the MCCB can ensure the most effective protection without unnecessary tripping due to minor fluctuations.

- Future-Proofing: For future EV charger upgrades, the adjustable MCCB can be adapted to accommodate a different charger with a varying current rating.

- System Harmony: In complex EV charger installations with multiple EV chargers, adjustable MCCBs allow for customized EV charging load management for each charger, optimizing overall system performance.

James Ndungu is a certified EV charger installer with over five years of experience in EVSE selection, permitting, and installation. He holds advanced credentials, including certification from the Electric Vehicle Infrastructure Training Program (EVITP) and specialized training in EV charging equipment and installation, as well as diplomas in EV Technology and Engineering Fundamentals of EVs. Since 2021, James has tested dozens of EV chargers and accessories, sharing expert insights into the latest EV charging technologies.