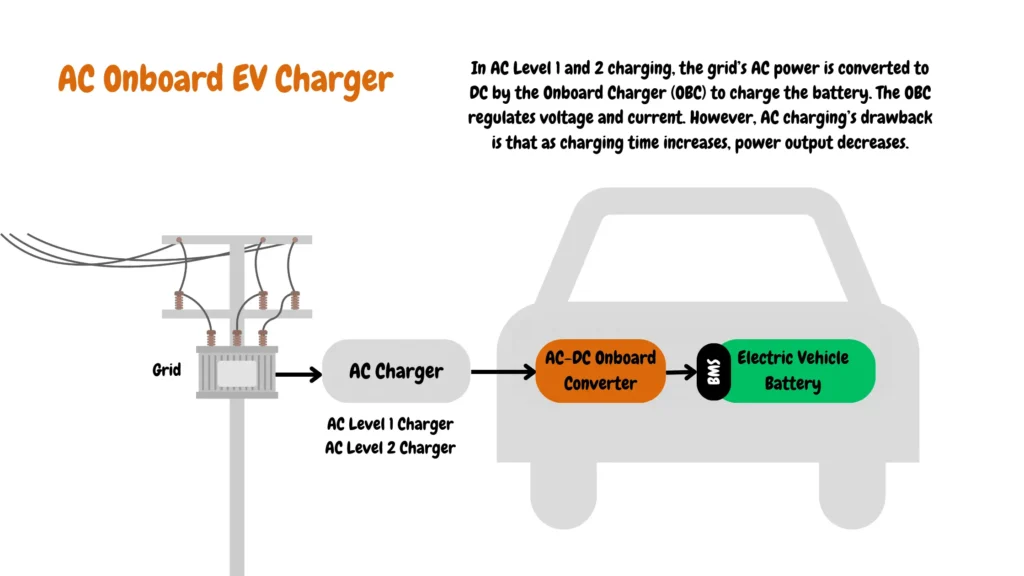

An Onboard EV Charger (OBC) is a device inside an electric vehicle (EV) that helps charge the battery when you plug into a regular AC power source. It changes Alternating Current (AC) from the grid into Direct Current (DC), which the battery needs to store energy safely.

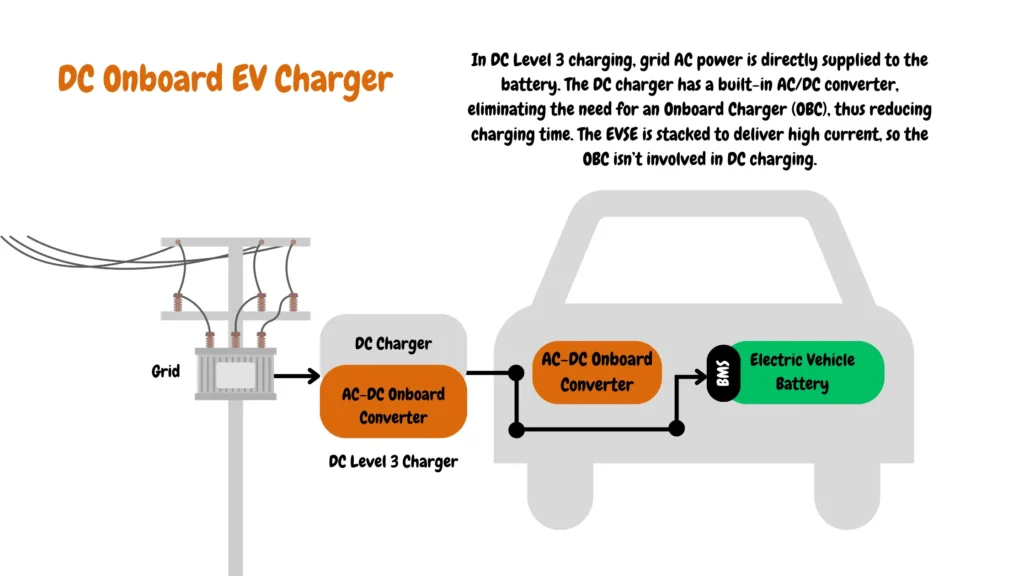

However, during DC fast charging, the AC-to-DC conversion does not happen inside the vehicle. Instead, the conversion equipment is built into the DC fast charger itself. The station converts AC power to DC and delivers it directly to the battery, bypassing the Onboard Charger entirely, to achieve much faster speeds, often ranging from 50 kW to 350 kW.

While we call these external boxes “chargers” in our EV charger reviews, manufacturers like Tesla remind us that the actual charger is the on-board charger built into your EV. The box on your wall is technically an EVSE (Electric Vehicle Supply Equipment).

How Does an EV Onboard Charger Work?

When you plug into a Level 1 or Level 2 AC charger, electricity flows through the cable to the onboard charger (OBC). The OBC manages the power in two steps:

- Power Factor Correction (PFC): The OBC first converts AC power from the wall to DC power, efficiently using energy and maintaining stable electricity.

- DC-DC Conversion: Next, it adjusts the voltage and current to match what the battery needs. This step safely changes the power (for example, from 240V AC to 400V+ DC) so the battery cells can charge properly.

Key Responsibilities of the Onboard EV Charger (OBC)

- Safety & Regulation: The OBC watches the battery’s temperature and voltage. It prevents overcharging by slowing the power as the battery gets full.

- Communication: Before charging, the OBC does a “digital handshake” with the charger to make sure everything is safe and agrees on the fastest power it can use.

- Charging Strategy: It usually starts with a Constant Current (CC) phase to charge quickly, then switches to Constant Voltage (CV) to finish safely.

Onboard EV Charger (OBC) Charging Strategy

There are two main types of charging strategy/methods that the OBC can use:

- Constant Current (CC): This method is efficient and fast, but there’s a risk of overcharging the EV battery, which could reduce its lifespan.

- Constant Voltage (CV): This method can charge the battery rapidly, but it might cause too much current to flow at the beginning of the charging process, potentially overheating the EV battery and shortening its lifespan.

The OBC typically starts with constant current charging for speed and efficiency to balance these factors. Then, when the battery voltage reaches a certain level, it switches to constant voltage charging. This strategy helps to optimize the charging process and prolong the battery’s lifespan.

Types of Onboard EV Chargers

Electric vehicles ‘ onboard chargers (OBCs) can be broadly classified into two types based on the power supply they use: single-phase (AC Onboard Chargers) and three-phase (DC Onboard Chargers).

AC Onboard EV Chargers (Single-Phase Onboard Chargers)

AC onboard chargers are built into every electric vehicle and serve as the critical link between your home’s power supply and the car’s battery. They convert Alternating Current (AC) from the grid into Direct Current (DC) that can be stored in the battery. These chargers are most commonly used for Level 1 and Level 2 home charging, delivering power outputs ranging from 1.5 kW to 22 kW, depending on the vehicle’s onboard system.

Electric vehicle battery size plays a key role in AC onboard charger ratings because it directly affects how much energy the vehicle needs to store and how quickly it can safely accept that power. Fully electric vehicles (EVs) have much larger battery capacities, allowing them to accommodate higher-capacity AC onboard chargers (commonly 7 kW to 11 kW, and up to 22 kW in premium models). This enables faster AC charging to replenish the larger energy reserves.

In contrast, plug-in hybrid electric vehicles (PHEVs) have smaller battery packs (typically under 20 kWh), designed for shorter electric-only ranges. Because these batteries require less energy to charge and generate more heat when charged too quickly, manufacturers equip them with lower AC onboard charger ratings (usually 3.3 kW to 7 kW) to ensure battery longevity, cost efficiency, and compatibility with standard home circuits.

AC Onboard EV Chargers by Vehicle Manufacturer

Below is a quick reference table showing common EV and PHEV models, their AC onboard charger ratings, and the maximum AC charging power they support. Understanding your vehicle’s onboard charger capacity helps you choose the right EV charger for the fastest, most efficient charging experience.

| Vehicle Manufacturer | Popular EV / PHEV Models (USA) | Onboard Charger Rating (Single-Phase AC) |

|---|---|---|

| Alfa Romeo | Tonale Plug-in Hybrid | 7.4 kW |

| Audi | Q4 e-tron, Q8 e-tron, e-tron GT | 9.6 kW (Q4), 9.6 kW (Q8), 9.6 kW (e-tron GT) |

| Bentley | Bentayga Hybrid, Flying Spur Hybrid | 7.2 kW |

| BMW | i4, i5, i7, iX | 11 kW |

| Chevrolet | Bolt EV, Bolt EUV, Blazer EV, Equinox EV, Silverado EV | 11.5 kW (Blazer, Equinox), 11 kW (Bolt EV/EUV) |

| Fiat | 500e | 11 kW |

| Ford | Mustang Mach-E, F-150 Lightning, E-Transit | 11.5 kW |

| Genesis | GV60, Electrified G80, Electrified GV70 | 11 kW |

| Honda | Prologue | 11.5 kW |

| Hyundai | Ioniq 5, Ioniq 6, Kona Electric | 10.9 kW (Ioniq 5/6), 7.2 kW (Kona Electric) |

| Jaguar | I-PACE | 11 kW |

| Jeep | Grand Cherokee 4xe (PHEV), Wrangler 4xe (PHEV) | 7.2 kW |

| Kia | EV6, EV9, Niro EV | 11 kW |

| Land Rover | Range Rover PHEV, Range Rover Sport PHEV | 7.2 kW |

| Lexus | RZ 450e | 6.6 kW |

| Lucid Motors | Air | 19.2 kW |

| Maserati | Grecale Folgore, GranTurismo Folgore, GranCabrio Folgore | 22 kW |

| Mazda | MX-30 | 6.6 kW |

| Mercedes-Benz | EQB, EQE, EQS (Sedan/SUV), Maybach EQS SUV | 9.6 kW |

| MINI | Cooper Electric, Countryman Electric | 7.4 kW (EV) / 3.6 kW (PHEV) |

| Mitsubishi | Outlander PHEV | 3.7 kW |

| Nissan | Leaf, Ariya | 6.6 kW |

| Polestar | Polestar 2, Polestar 3 | 11 kW |

| Porsche | Taycan, Panamera S E-Hybrid | 9.6 kW (Standard) / 19.2 kW (Optional) |

| Rivian | R1T, R1S | 11.5 kW |

| Rolls-Royce | Spectre | 11 kW |

| Subaru | Solterra | 6.6 kW |

| Tesla | Model S, Model 3, Model X, Model Y, Cybertruck | 11.5 kW |

| Toyota | bZ4X, Prius Prime (PHEV), RAV4 Prime (PHEV) | 6.6 kW |

| Volkswagen | ID.4 | 11 kW |

| Volvo | XC40 Recharge, C40 Recharge, EX30, EX90 | 11 kW |

Below is a quick reference table showing common EV and PHEV models, their onboard charger ratings, and the maximum AC charging power they support. Understanding your vehicle’s onboard charger capacity helps you choose the right home charger for the fastest, most efficient charging experience.

DC Onboard EV Chargers (Three-Phase Onboard Chargers)

These chargers allow the vehicle to be charged directly with Direct Current (DC) from a charging station. They bypass the car’s onboard charger for faster charging. These chargers are typically found in public charging stations and can deliver power from 50 kW to over 350 kW.

Onboard chargers have varying requirements when it comes to the system-level charging functions in battery electric vehicles (BEVs), plug-in hybrid electric vehicles (PHEVs), and, in the near future, fuel cell electric vehicles (FCEVs).

| Onboard Charger Parameters | Currently, Less than 400V, some 800V, and wide adoption of 800V. | Plug-in Hybrid Electric Vehicles (PHEVs) or Fuel Cell Electric Vehicles (FCEVs). |

|---|---|---|

| Output Power | <11kW in todays EVs, Adoption of 22kW in Fast Charging EVs | <7.2kW, Migration to high power for fast charging |

| AC Power | Single Phase and Three Phase Installation | Single Phase and Three Phase Installation |

| DC Fast Charge Bypass | Yes | Limited offerings, may see more in the near future |

| Cost | High Cost | Low Cost |

| Battery Pack Voltage | Currently, Less than 400V, some 800V, and Wide adoption of 800V. | Less than 400V |

Onboard EV Charger in AC & DC Charging.

On an AC Charger, the Onboard EV Charger is found on the electric vehicle, while on a DC Charger, it is found on the electric vehicle itself.

An Onboard EV Charger (OBC) in AC Charging

AC chargers with an inbuilt onboard charger are standard in-home EV chargers, also known as Level 1 and Level 2 home EV Chargers, which use AC Current with power outputs of 1.5 kW to 22 kW. AC Chargers rely on Onboard EV chargers to convert AC to DC currents.

The AC charger also depends on the Onboard EV Charger to control the charging speeds, with most Onboard EV Chargers in electronic vehicles accepting up to 7kW.

An Off-Board EV Charger (OBC) in DC Charging

DC chargers, also known as Level 3 or Fast EV chargers, have an off-board charger built that converts AC to DC in the chargers themselves; they are common in public stations and deliver power from 50 kW to over 350 kW and are known to bypass an electric vehicle’s Onboard EV Charger for faster charging.

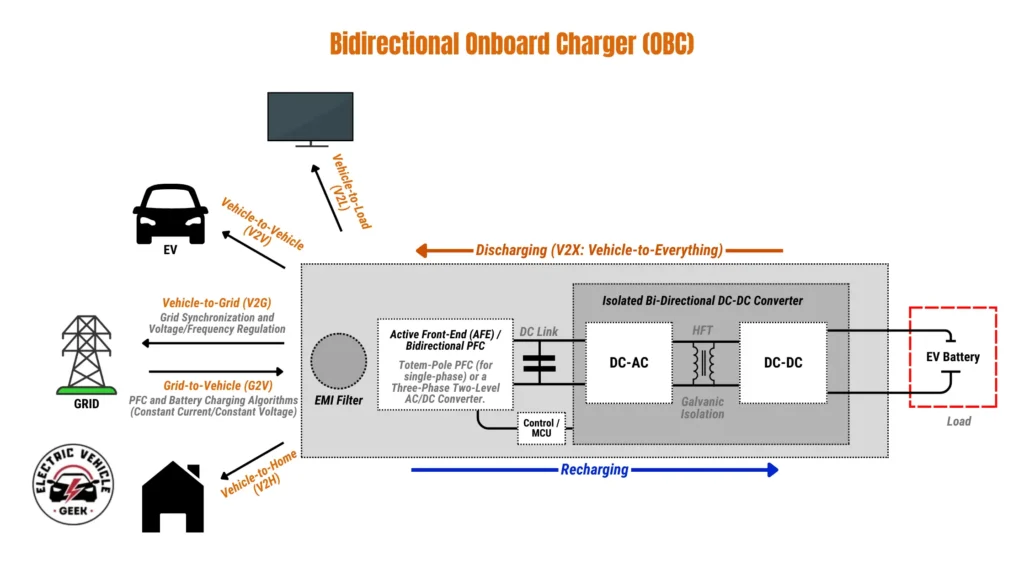

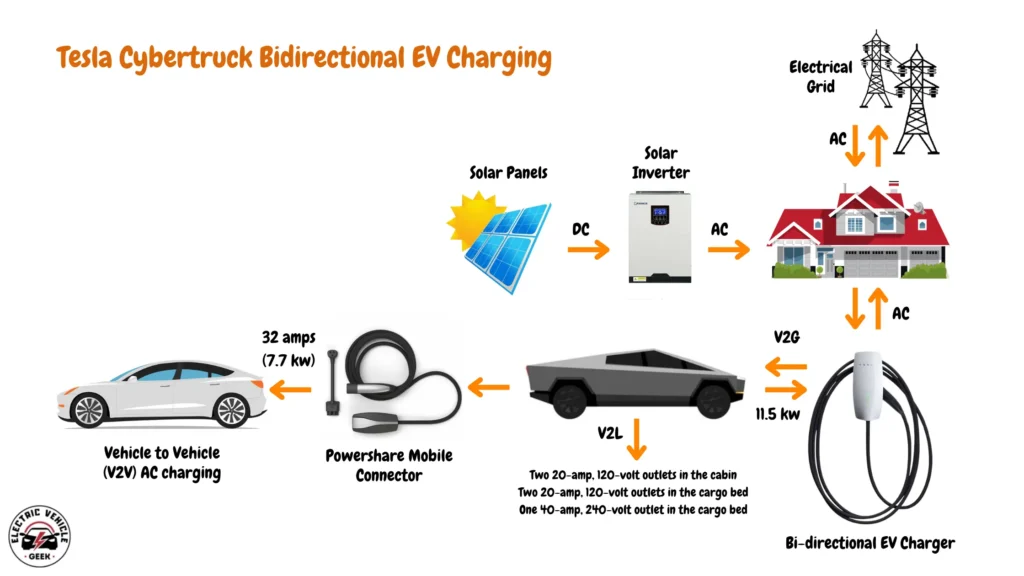

Bidirectional Onboard EV Chargers (BOBCs)

Modern bidirectional Onboard EV Chargers (BOBCs) can flow power both ways. They convert the electric vehicle (EV) battery’s direct current (DC) power back into alternating current (AC) to power your home (Vehicle-to-Home, V2H), send electricity to the grid (Vehicle-to-Grid, V2G), or even share power with another vehicle (Vehicle-to-Vehicle, V2V).

Bidirectional Onboard Chargers (BOBCs) work with a bidirectional EV charger, such as the Tesla Universal Wall Connector, and compatible vehicles like the Tesla Cybertruck.

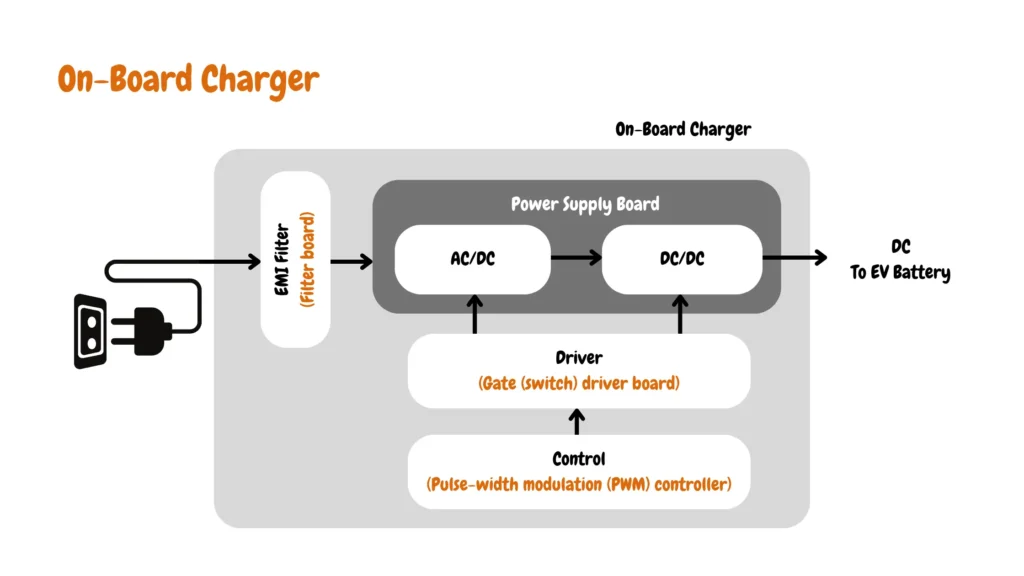

Onboard EV Charger Components

The Onboard EV Charger (OBC) in electric vehicles consists of four main printed circuit boards (PCBs) – Filter board, Power Supply Board, Control Board, and Driver Board, as shown in the image below:

Onboard EV Charger Filter Board

Also known as the EMI filter board, it filters out two types of Electromagnetic Interference (EMI) noise – Differential Mode (DM) and Common Mode (CM). DM noise is conducted on the line and neutral in opposite directions, while CM noise is conducted on both the line and neutral in the same direction.

Onboard EV Charger Power Supply Board

It comprises two parts – AC-DC and DC-DC. The AC-DC part, often called a rectifier, converts AC to DC and includes a Power Factor Correction (PFC) function to measure how efficiently electrical power is used.

The DC-DC part converts DC to DC (either step up or down), maintaining a constant output voltage regardless of load current or variations in the supply voltage.

Onboard EV Charger Control Board

The control board, consisting of a microcontroller (MCU), acts as the ‘brain’ and sends Pulse-Width Modulation (PWM) signals to the driver board.

Onboard EV Charger Driver Board

The driver board interfaces between the MCU and the gates/switches on the power supply board, driving them to open or close.

James Ndungu is a certified EV charger installer with over five years of experience in EVSE selection, permitting, and installation. He holds advanced credentials, including certification from the Electric Vehicle Infrastructure Training Program (EVITP) and specialized training in EV charging equipment and installation, as well as diplomas in EV Technology and Engineering Fundamentals of EVs. Since 2021, James has tested dozens of EV chargers and accessories, sharing expert insights into the latest EV charging technologies.