We put together this detailed breakdown of essential EV charger safety features to complement our EV charger buyer’s guide and EV charger safety guidelines. At Electric Vehicle Geek, EV charging safety is our mission, and it starts with choosing an EV charger built to meet the highest safety standards..

Understanding these safety features not only promotes better charging habits but also helps prevent electrical hazards, equipment failures, and property damage.

Table of Contents

Expert Tip

When buying a home EV charger, make sure it has important safety certifications. Look for UL 2594 for Level 2 chargers and UL 2202 for fast chargers. Other important standards include UL 2231, IEC 61851, IEC 62752, and IEC 62955. The charger should also have marks from trusted labs like ETL, CSA, or TÜV, and meet rules like CE and FCC for safety and quality.

The installation must follow the National Electrical Code (NEC) Article 625, plus guidelines from NFPA and EVITP. These rules make sure the wiring, breakers, and grounding keep your home and vehicle safe while charging. Safety starts with certified equipment and proper installation.

EV Charger Safety Features to Consider

Here are the key EV charger safety features to look for when choosing an EV charger:

Built-In Protection Features

In our EV charger rating system, the “Features” category evaluates several key EV charger features, including core functionality, hardware quality, safety protections, smart charging, user convenience, and aesthetic features. Among these, safety features carry the most weight to us as experts when evaluating an EV charger’s features.

EV charger safety features are designed to help prevent overheating, electrical faults, ground faults (earth leakage), voltage drops, surges, overcurrents, and EV charging-related fire hazards, including EV battery fires, which can be triggered by poor connections or unsafe charging equipment. Chargers with built-in safety mechanisms that ensure proper coupling between the charger and vehicle significantly reduce these risks.

When shopping for an EV charger, prioritize the safety features listed below. They’re essential for safe home charging and are consistently found in models that score highest in our features rating. In our EV charger reviews, look for chargers with a features score of 9.0–9.7 (very high) or 9.8–10 (highest). These models offer premium safety features and meet leading U.S. electrical safety standards.

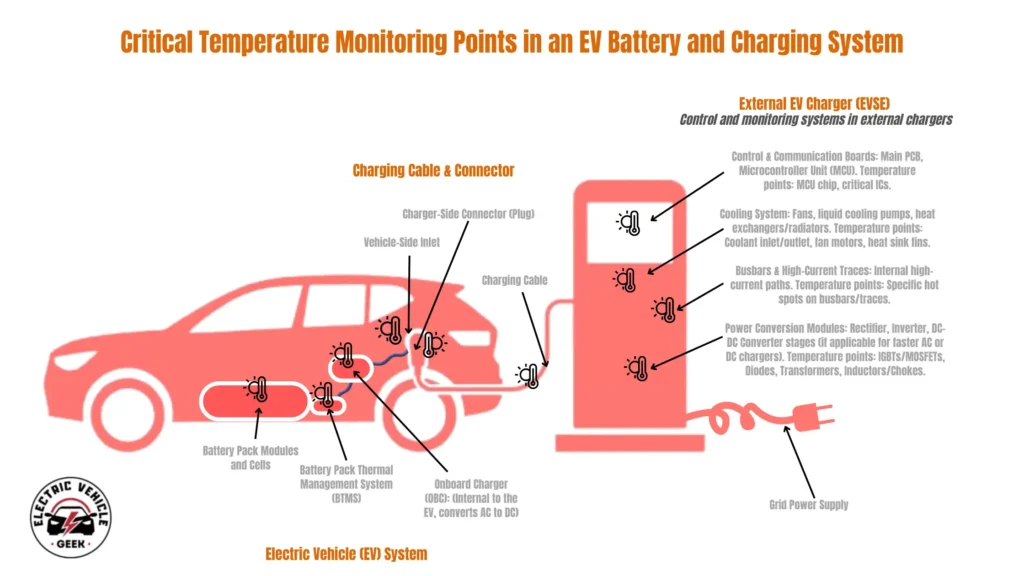

Temperature Sensors

Overheating is a common issue with low-quality EV chargers. It often occurs at the plug or connector due to poor internal wiring, inferior materials, or the lack of temperature monitoring.

EV chargers with the highest “Features” ratings in our reviews include built-in thermal protection at key points where heat buildup is most likely, such as the plug, charging cable, wall unit terminals, circuit board, power cable, and mains plug on plug-in models.

When choosing a home EV charger, look for models with built-in temperature sensors in the plug, cable, circuit board, and power connections. These sensors help prevent overheating during full-load charging or long sessions by shutting down or adjusting current if temperatures exceed safe limits.

EV chargers without temperature sensors may not comply with NEC 625.17(A), which requires safe temperature control at the connection point between the charger and the vehicle. The lack of this protection increases the risk of melted plugs, electrical damage, and potential fire hazards.

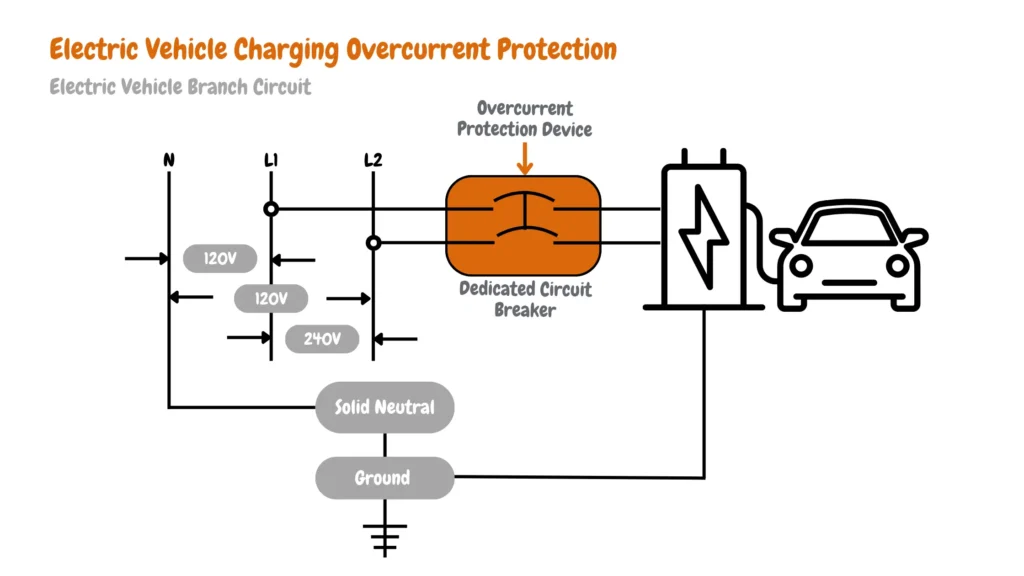

Overcurrent & Overvoltage Protection

Power surges, voltage spikes, and grid faults pose serious risks to EV chargers and connected vehicles. Without proper protection, these events can cause electrical damage, charger failure, or even fire.

EV chargers with built-in overcurrent and overvoltage protection that comply with NEC 240.4 (conductor protection), NEC 625.22 (EVSE protection), and NFPA 70 (fire prevention) ensure safe disconnection during overloads, short circuits, or voltage transients from grid disturbances or lightning strikes.

Overcurrent protection is paramount to safeguard the charging circuit, the EVSE, and the connected electric vehicle from damage due to sustained overloads or short-circuit events. Every EV charger should be installed on a dedicated branch circuit to isolate it from other household loads.

In NEC jurisdictions, Article 240 requires overcurrent protection for continuous loads like EV charging to be sized at 125% of the EVSE’s continuous rated current, typically implemented using a correctly rated circuit breaker. IEC 61851-1 applies similar principles in international installations.

This protection is especially critical in homes with aging panels, unstable grids, or shared circuits where voltage irregularities are more frequent. When selecting a charger, confirm it includes internal overcurrent protection, typically listed under “Safety Features” or “Technical Specifications.”

Higher-end EV chargers may also integrate DC leakage detection (RDC-DD), which detects smooth DC fault currents ≥6mA. These must be paired with an upstream Type A RCD (30mA trip sensitivity) to ensure effective AC ground fault protection.

If the charger lacks an RDC-DD, a more expensive Type B RCD is required instead, as it detects AC, pulsating DC, and smooth DC leakage. While Type B devices are costlier, they reduce nuisance EV charger circuit breaker tripping and offer the highest level of safety for fault current protection.

Lack of this protection significantly increases the risk of electrical hazards and can compromise both charger longevity and vehicle battery health.

Learn more in our complete guide to Electric Vehicle Charging Overcurrent Protection.

Short Circuit Protection

Short circuit protection is a core safety feature in all high-quality EV chargers. It instantly cuts off power when a fault is detected, such as a direct line-to-line or line-to-ground connection, preventing high-current flow that can lead to arcing, melted components, or fire.

Premium chargers in our reviews include fast-acting internal circuit breakers or solid-state relays that isolate faults within milliseconds. This protects not only the EV charger and the vehicle’s onboard systems but also the home’s electrical infrastructure from catastrophic failure.

In a typical home installation, EV charging short circuit protection is implemented at two levels:

- External Protection (Primary & Mandatory): Located in the home’s main electrical panel, using high-speed dedicated EV charger circuit breakers with appropriate interrupting ratings (e.g., 10kA AIC for residential systems) to safely disconnect power in the event of a fault.

- Internal Protection (Integrated in the EV Charger): Includes onboard fuses, miniature circuit breakers (MCBs), RCBOs, or solid-state protection mechanisms. Some chargers also leverage Control Pilot signaling (IEC 61851-1) to detect and shut down abnormal conditions preemptively.

Importantly, short circuit protection is a code requirement under NEC 110.10, which mandates that all equipment must be able to limit and withstand fault energy. It is also required under NEIS (National Electrical Installation Standards) for compliant EVSE installations, especially in garages or multi-unit dwellings.

Short-circuit protection in EV chargers is governed by multiple international and national safety codes, including:

- IEC 61851-1 – General requirements for AC electric vehicle charging systems, including overcurrent and short-circuit safety.

- IEC 61851-23 – Specific to DC fast charging systems.

- IEC 62196 Series – Standards for EV plugs and connectors, which include short-circuit withstand specifications.

- NEC Article 240 – U.S. installation rules for circuit breakers and protective devices.

- UL 2231 / UL 943 – UL safety certifications for EVSE equipment, including short-circuit and ground fault testing.

When evaluating EV chargers, always confirm that the unit complies with these standards and includes properly rated short-circuit protection. Chargers lacking this protection pose a significant risk to both the vehicle and home, and may violate electrical code or void insurance coverage in the event of a fault.

Ground Fault (Electric Leakage) Protection

Prevents electric shock by cutting power when leakage current is detected, required for safe residential and commercial EV charging.

Ground fault protection is a critical safety feature in any EV charger, designed to prevent electric shock by immediately cutting power if leakage current is detected between live conductors and ground. This type of protection is essential in environments prone to moisture, such as outdoor installations, wet garages, or situations involving damaged charging cables.

Our top-rated EV chargers in the Features category, the Tesla Universal Wall Connector and Tesla Wall Connector, feature advanced ground monitoring circuits that continuously verify a safe ground. These chargers automatically detect and clear faults, eliminating the need for manual resets. Even in tough environments like ground faults or during power surges, they ensure safe, reliable, and uninterrupted charging. utility power surges

In the event of a temporary issue, such as a utility power surge or minor ground fault, the charger intelligently pauses, clears the fault, and re-attempts charging once conditions stabilize. This ensures uninterrupted performance while maintaining the highest level of electrical safety for both users and vehicles.

Standard breakers don’t trip at the low current levels that can cause injury or death. Ground fault protection fills this gap, providing fast disconnection before harm occurs.

Built-in Ground Fault Circuit Interrupters (GFCIs) or Residual Current Devices (RCDs) monitor for imbalances in current. If more current is flowing out than returning, typically caused by leakage to ground, the unit trips and stops charging.

EV chargers must detect smooth DC leakage currents caused by faults in the EV’s onboard systems. Not all RCD types are suitable:

- RDC-DD + Type A RCD (Common in Residential EVSE): A Residual Direct Current Detection Device (RDC-DD) built into the charger detects ≥6mA of DC leakage and signals an upstream Type A RCD (30mA) to trip. This setup meets IEC 62955 and UL 2231 standards.

- Type B RCD (Required in Commercial Installations or When No RDC-DD Exists): Detects AC, pulsating DC, and smooth DC currents. Offers the most comprehensive protection and is often required for public charging stations or non-RDC-DD units.

Ground fault protection in EV chargers is mandated by several critical electrical safety standards. Under NEC 625.22, ground fault protection is required to be included in all EV supply equipment (EVSE). Additionally, GFCI protection is mandated by NEC 210.8(A) and 210.8(F) for EV charging outlets, such as NEMA 14-50, particularly when they are installed in garages or outdoor environments.

In North America, UL 2231 and OSHA electrical safety guidelines define the required performance and personnel protection standards for EVSE. Internationally, IEC 61851-1 and IEC 62955 outline ground fault and DC leakage protection requirements for AC electric vehicle chargers, ensuring consistent global safety compliance.

When shopping for an EV charger, it’s important to ensure it includes integrated 20mA ground fault protection (CCID20) or 6mA RDC-DD detection to meet safety requirements for personnel protection. Look for chargers that carry a UL 2231 listing or are compliant with IEC 62955, both of which confirm the unit meets recognized standards for leakage detection.

If the charger lacks internal DC fault detection, a Type B RCD or an external GFCI breaker should be installed to ensure full protection. For installations in wet or outdoor environments, an outdoor-rated EV charger enclosure with at least a NEMA 4 or IP66 rating is recommended to protect against water intrusion and maintain safe operation.

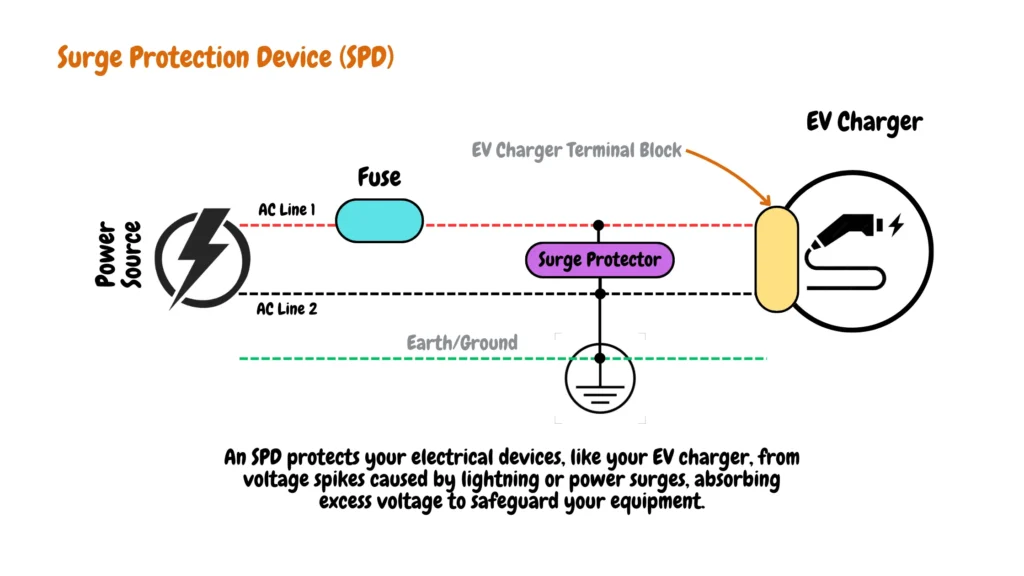

Lightning/ Surge Protection

EV chargers, especially outdoor EV chargers, are highly vulnerable to high-voltage electrical surges, shocks, and other circuit irregularities. A high-quality EV charger, especially an outdoor EV charger, should include internal surge protection to safeguard circuit boards from transient overvoltages caused by lightning strikes or utility grid switching. Read our full EV Charger Surge Protection Guide.

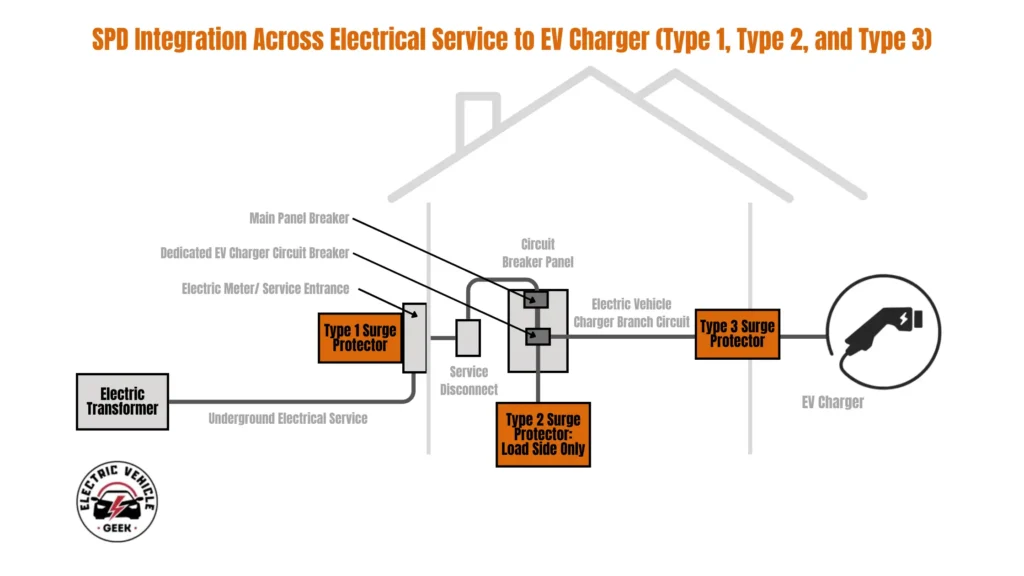

When shopping for EV chargers, choose a model with a built-in Type 3 surge protection device (SPD), especially for outdoor use, and protect your home’s electrical panel with Type 1 or Type 2 SPDs. This layered lightning/ surge protection helps shield your EV charger, electric vehicle, and charging accessories from voltage spikes caused by lightning or utility grid disturbances. Learn more about Surge Protective Devices (SPDs).

When shopping for EV chargers, choose EV chargers with built-in Type 3 SPDs, especially when shopping for an outdoor EV charger, and protect your home electrical panel with Type 1 or Type 2 SPDs to shield your EV charger, electric vehicle, and EV charging accessories from voltage spikes caused by lightning or grid disturbances. Learn more about Surge Protective Devices (SPDs).

A layered surge protection strategy using Type 1 and/or Type 2 SPDs upstream, along with integrated Type 3 protection at the charger, ensures transient overvoltages are gradually reduced before reaching sensitive EVSE electronics. Because Type 3 SPDs inside EV chargers are only rated to handle low-level residual surges, they are not sufficient on their own and must be paired with upstream protection devices capable of safely diverting higher energy surges from lightning or grid disturbances.

We recommend Type 2 Surge Protection Devices (SPDs) as the most appropriate choice for residential and light commercial EV charger installations. There are two main installation options: a dedicated Type 2 SPD for the EV circuit or a whole-house Type 2 SPD installed at the main panel.

We recommend choosing a whole-house Type 2 SPD, such as the Siemens BoltShield FSPD140, which is a cost-effective solution that protects not only your EV charger but also other sensitive electronics connected to your electrical panel.

Siemens Boltshield FSPD140 Whole-House SPD for EV Charger Protection

Effective EV charger grounding and bonding are just as critical; chargers must be connected to a low-impedance earthing system to safely redirect surge energy. In areas prone to lightning or for rooftop/wall-mounted EVSEs, consider an external lightning protection system (LPS) to divert direct strikes. Lastly, choose a model with a weather-sealed enclosure (IP55 or higher) to prevent moisture ingress, which can compromise insulation and increase surge risk.

These protections support NFPA lightning strategies, comply with NEC Article 285, and align with international standards like IEC 61643, IEC 62305, and IEC 60364-5-534, ensuring safety and equipment longevity in outdoor environments.

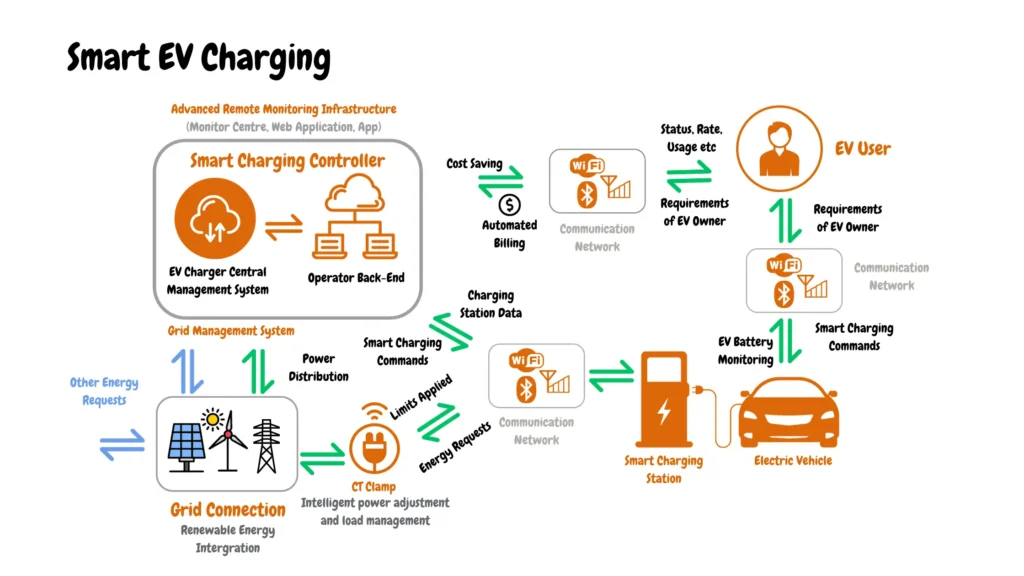

Smart Charging Recovery: Auto Shutoff and Restart Logic

Modern EV chargers use intelligent shutoff and restart systems to ensure safe, reliable smart EV charging, especially during power fluctuations, grid disturbances, or system faults.

Auto shutoff logic protects both the charger and vehicle by stopping power when a problem is detected. This includes overcurrent, ground faults, voltage irregularities, overheating, or loss of communication between the charger and EV. Charging also stops automatically when the battery is full, the cable is unplugged, or a scheduled charging session ends.

Smart chargers also shut off in response to external signals. These can include demand response events, time-of-use pricing, or dynamic load balancing, allowing the charger to reduce or pause charging to protect the home’s electrical system or respond to grid conditions.

The restart logic kicks in once the issue clears. After a power outage, for example, the charger can automatically resume charging, usually after a short safety delay, such as 3 minutes, to allow the system to stabilize.

Before restarting, the charger checks that voltage levels are safe, the fault is cleared, and the EV is still connected and ready to charge. Some chargers also evaluate household load or time-based charging schedules before restarting.

In networked or commercial setups, restart logic can include automated diagnostics. Advanced systems may reboot the charger remotely or retry charging multiple times if a transient issue is detected.

Smart charging recovery features ensure safe fault recovery, protect your investment, and help optimize charging efficiency. When choosing a charger, look for models with intelligent shutoff and auto-restart logic to improve safety, reduce downtime, and enhance the user experience.

James Ndungu is a certified EV charger installer with over five years of experience in EVSE selection, permitting, and installation. He holds advanced credentials, including certification from the Electric Vehicle Infrastructure Training Program (EVITP) and specialized training in EV charging equipment and installation, as well as diplomas in EV Technology and Engineering Fundamentals of EVs. Since 2021, James has tested dozens of EV chargers and accessories, sharing expert insights into the latest EV charging technologies.