One of the most important concepts in EV charger installation is the 125% NEC rule, which determines the correct breaker size and wiring for EV charging continuous loads. If you’ve ever wondered why your 40A EV charger requires a 50A breaker, or why electricians always talk about “continuous load derating,” this guide will walk you through it step by step.

With over 30 years of electrical code evolution, high-amperage equipment like EV chargers has pushed the NEC to refine how circuits are sized for continuous, high-demand loads. Let’s break down not just what the 125% rule requires, but also why it exists and how it directly impacts your EV charger installation.

Table of Contents

What is the 125% Rule?

The “NEC 125% Rule for EV Chargers” requires that both the dedicated EV charger circuit breaker (overcurrent protection) and the conductors serving Electric Vehicle Supply Equipment (EVSE) must be rated for at least 125% of the equipment’s maximum continuous load. This requirement is established in NEC Article 210.19(A)(1) (conductor sizing), NEC Article 210.20(A) (overcurrent protection sizing), and NEC Article 625.42 (EVSE as a continuous load).

Are EV Chargers Considered a Continuous Load?

Yes, EV charging is classified as a continuous load under the National Electrical Code (NEC). According to NEC Article 100, a continuous load is “a load where the maximum current is expected to continue for three hours or more.”

Because EVs often charge overnight or for extended periods, they clearly meet this definition. For that reason, the NEC requires all EV charger branch circuits, conductors, and overcurrent protection devices (breakers) serving EV chargers to be sized at 125% of the charger’s rated continuous load.

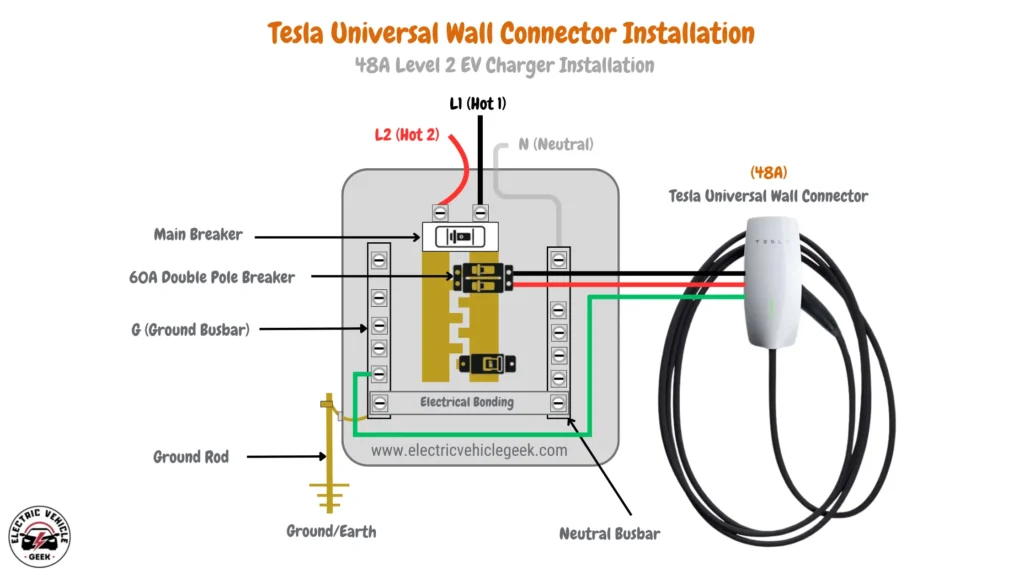

Example: Tesla Universal Wall Connector (48A Configuration)

The Tesla Universal Wall Connector can deliver up to 48 Amps continuously. Since EV charging is defined as a continuous load (NEC Article 100), the NEC 125% rule applies:

48A × 125% = 60A

This means you must install a 60A dedicated breaker with appropriately sized conductors for a 48A EV charger.

As shown in the circuit diagram below, the breaker should be installed in your main service panel (or subpanel if dedicated), feeding the conductors that run directly to the Wall Connector. This ensures compliance with NEC 210.19(A)(1) (branch circuit conductor sizing) and NEC 625.42 (EVSE continuous load).

Why Does the NEC Require This Rule?

The 125% rule exists for safety margins and heat management.

- Breakers and wiring are tested and rated under ideal conditions. But in the real world, wires heat up under load, breakers trip later than expected, and connections may loosen over time.

- Continuous EV charging loads for hours (as in EV charging) push electrical systems harder than short, intermittent loads like an oven or dryer.

- By requiring a 25% headroom, the NEC ensures the system runs cooler, reduces fire risk, voltage drops, and extends the life of the components.

Think of it as building in a buffer; your charger may only draw 40A, but the circuit must be sized to handle 50A safely over many years of daily use.

How Does This Apply to EV Charging?

EV chargers (technically called EVSE – Electric Vehicle Supply Equipment) are listed as continuous loads by definition in NEC 625.42.

That means:

- You can’t ignore the 125% rule. Every EVSE installation must follow it.

- Charger settings matter. Some chargers allow adjustable amperage (e.g., settable between 16A and 48A). Whatever maximum continuous current you set must be multiplied by 125% for breaker sizing.

- Misunderstanding the rule leads to mistakes. Many DIY installers assume “a 40A charger just needs a 40A breaker.” That’s incorrect and violates the code.

Common EV Charger Setups Explained

Let’s look at how the 125% rule applies to real-world EV charger sizes:

| EV Charger Amperage | NEC 125% Calculation | Recommended Breaker | Typical Wire Gauge |

|---|---|---|---|

| 12 Amp EV Chargers | 12A × 1.25 = 15A | 15A | 14 AWG |

| 16 Amp EV Chargers | 16A × 1.25 = 20A | 20A | 12 AWG |

| 24 Amp EV Chargers | 24A × 1.25 = 30A | 30A | 10 AWG |

| 32 Amp EV Chargers | 32A × 1.25 = 40A | 40A | 8 AWG |

| 40 Amp EV Chargers | 40A × 1.25 = 50A | 50A | 6 AWG |

| 48 Amp EV Chargers | 48A × 1.25 = 60A | 60A | 6 AWG |

| 50 Amp EV Chargers | 50A × 1.25 = 62.5A | 70A | 4 AWG |

| 80 Amp EV Chargers | 80A × 1.25 = 100A | 100A | 3 AWG |

Notice the pattern? The breaker is always the next standard size up after applying the 125% rule.

When shopping for an EV charger, you’ll notice manufacturers often advertise “maximum output” alongside “recommended circuit size.” That’s the 125% rule baked into the spec sheet.

- For a detailed breakdown of breaker sizing, see our [Electric Vehicle Charger Circuit Breaker Selection Guide].

- To learn how to match wire gauge to your EV charger, check out our [Choosing the Right EV Charger Wire Gauge].

By combining both resources, you’ll have a complete picture of how to properly size your EV charger branch circuit, select the right breaker, and choose a safe wire gauge for any EV charging installation.

NEC Code Sections That Apply

Here are the key NEC articles you should know:

- NEC 210.19(A)(1): Branch circuit conductor sizing, requiring 125% for continuous loads.

- NEC 210.20(A): Overcurrent protection device sizing for continuous loads.

- NEC 625.42: EVSE is defined as a continuous load.

- NEC 625.41: EVSE must be on a dedicated branch circuit (no sharing with other appliances).

Together, these articles create the framework that governs all EVSE installations in the U.S.

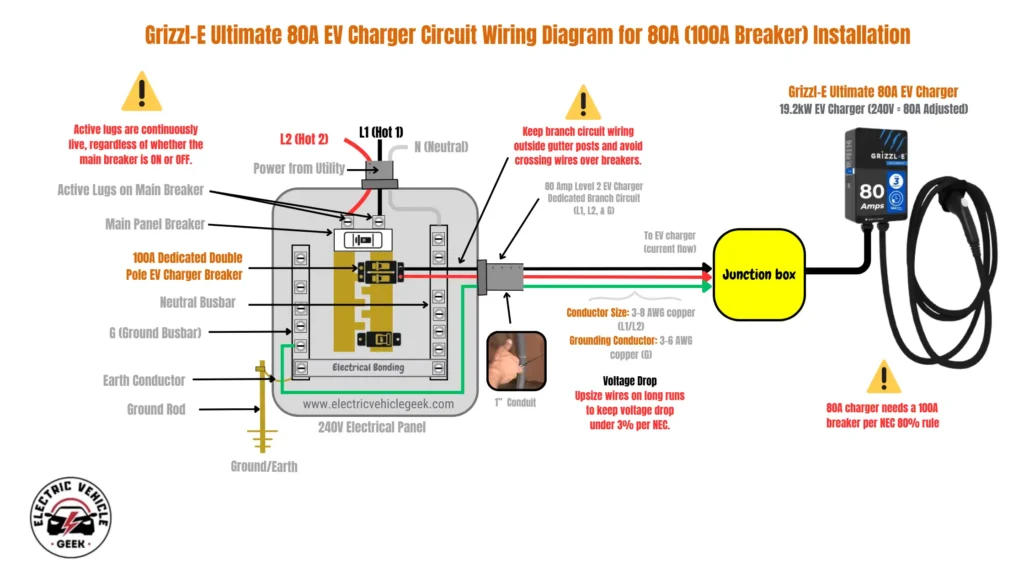

Practical Example: Installing the Grizzl-E Ultimate 80A Charger

Let’s walk through a real-world installation using a high-capacity unit like the Grizzl-E Ultimate 80A EV Charger:

- Charger spec sheet: Continuous output = 80A.

- 125% NEC rule: 80A × 125% = 100A minimum circuit.

- Breaker sizing: Install a 240V 100A two-pole breaker.

- Wiring: Use 3 AWG copper THHN conductors in conduit (or equivalent wiring approved by local code).

As shown in the Grizzl-E Ultimate 80A EV Charger circuit wiring diagram below, the breaker (100A two-pole), conductors (3 AWG copper THHN or equivalent), and charger (80A continuous) must all be sized correctly to handle the continuous load safely. Skipping any of these steps risks overheating, nuisance breaker trips, or inspection failure.

Common Mistakes to Avoid

- Undersizing the breaker: (e.g., putting a 40A charger on a 40A breaker).

- Ignoring adjustable amperage: if your charger is set to 48A, the breaker must be 60A, not 50A.

- Using undersized wire: breakers protect wires, not chargers. If the wire is too small, you create a fire hazard.

- Sharing circuits: EVSE must be on a dedicated circuit per NEC 625.41.

- Not checking local codes: some jurisdictions adopt NEC with amendments. Always confirm with your AHJ (Authority Having Jurisdiction).

Why This Rule Matters for Homeowners

If you’re planning to install an EV charger at home, here’s why understanding the 125% rule matters:

- Budgeting: A 50A or 60A circuit may cost more to install than you think. Larger wire, bigger breakers, and panel space add up.

- Future-proofing: If you plan to buy another EV, consider upsizing your circuit now. Installing a 60A circuit for a 48A charger may save you a second upgrade later.

- Safety & Insurance: An installation that doesn’t follow NEC could void warranties, fail inspection, or even cause insurance issues after a fire.

Final Thoughts

The 125% NEC rule isn’t just a code requirement; it’s a safety principle that keeps EV charging reliable, prevents overheating, and ensures your installation lasts for years.

By remembering this rule:

- Multiply continuous load × 125%

- Size breaker and wire accordingly

- Always use a dedicated circuit

…you’ll avoid the most common pitfalls of EV charger installation.

As EV adoption grows, electricians, inspectors, and homeowners all need to be fluent in the NEC 125% rule. This requirement takes what could be hidden electrical and EV charging risks (overheating, breaker trips, and undersized wiring) and makes them measurable, predictable, and preventable. It’s the foundation of safe, code-compliant EV charger installations.

James Ndungu is a certified EV charger installer with over five years of experience in EVSE selection, permitting, and installation. He holds advanced credentials, including certification from the Electric Vehicle Infrastructure Training Program (EVITP) and specialized training in EV charging equipment and installation, as well as diplomas in EV Technology and Engineering Fundamentals of EVs. Since 2021, James has tested dozens of EV chargers and accessories, sharing expert insights into the latest EV charging technologies.