Supported by you via insider access, and when you purchase through links on our site, we may earn an affiliate commission. See our Affiliate Disclosure.

Electric Vehicle Supply Chain

This section features my original research and collaborative articles on the evolving electric vehicle supply chain. I cover key EV supply chain ecosystem topics, including raw material sourcing, manufacturing, batteries, semiconductors, motors, chargers, thermal systems, software integration, distribution, energy supply, government policies, end-of-life recycling, etc.

Introduction to the EV Supply Chain

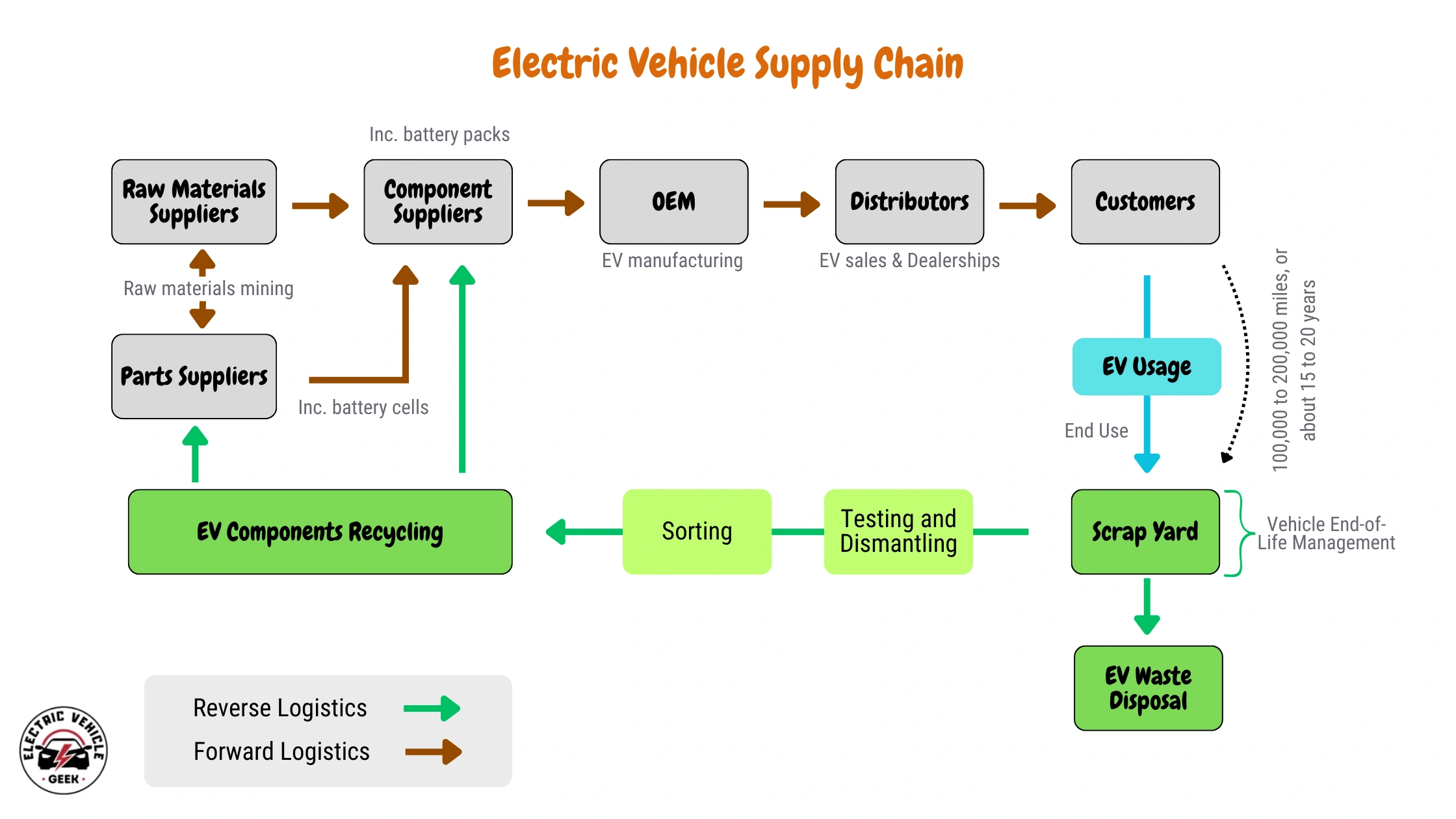

The electric vehicle supply chain is a complex supply chain ecosystem that includes sourcing raw materials, manufacturing components, assembling vehicles, and recycling at the end of life. It directly impacts the cost, availability, and sustainability of EVs while driving innovation in transportation. Electric vehicle supply chain is crucial to the global shift toward more eco-friendly mobility solutions.

The EV supply chain ecosystem consists of broader, interconnected network of all sub-supply chains involved in the production and distribution of electric vehicles. It integrates raw material suppliers, manufacturers, logistics providers, and recyclers to create a seamless flow of resources and products, driving the growth of the electric vehicle industry.

Electric Vehicle Nested Supply Chain or Sub-Supply Chain

A nested or sub-supply chain within the electric vehicle supply chain ecosystem refers to smaller, specialized supply chains that operate under the larger EV supply chain. These sub-supply chains manage specific components, products, or services with their suppliers, processes, and logistics, all contributing to the broader EV manufacturing and distribution process.

Benefits of Electric Vehicle Nested or Sub-Supply Chains

Highlighted below are some of the benefits of nested or sub-supply chain in the electric vehicle supply chain ecosystem

Specialization

Sub-supply chains enhance expertise in specific components or services, improving production quality and operational efficiency.

Reduced Complexity

Dividing the main supply chain into smaller sub-supply chains simplifies the system, making it easier to manage and oversee.

Flexibility and Agility

Sub-supply chains can adapt quickly to demand shifts or technological changes, boosting the overall responsiveness of the EV supply chain.

Cost Efficiency

Streamlining processes, sourcing materials efficiently, and optimizing logistics in sub-supply chains can lead to significant cost reductions.

Innovation

Focused sub-supply chains encourage innovation, propelling technological advancements that support the EV market’s growth.

Disadvantages of Electric Vehicle Nested or Sub-Supply Chains

Highlighted below are some of the disadvantages of nested or sub-supply chain in the electric vehicle supply chain ecosystem

Coordination Challenges

Managing multiple sub-supply chains can be difficult, particularly when aligning timelines, logistics, and production schedules.

Risk of Disruption

Disruptions in one sub-supply chain, such as material shortages or delays, can have ripple effects that impact the entire EV supply chain.

Increased Overhead

Multiple sub-supply chains require additional administrative and management resources, which can raise operational costs.

Dependence on External Suppliers

Streamlining processes, sourcing materials efficiently, and optimizing logistics in sub-supply chains can lead to significant cost reductions.

Quality Control

Sub-supply chains often rely on external suppliers for key components, creating risks if those suppliers face financial or operational issues.

Electric Vehicle Supply Chain Related Content

Check out related in-depth articles, insights, and updates on the electric vehicle supply chain, this collection offers valuable resources for anyone keen to understand the inner workings of the electric vehicle supply chain ecosystem.

Why I Started Electric Vehicle Supply Chain Section

With extensive experience in the electric vehicle industry, I have witnessed the sector’s rapid growth, driven by consumer demand for sustainability and regulatory pressures. However, this growth has introduced significant complexities and inefficiencies within the EV supply chain. The increasingly intricate network of suppliers and distribution centers, spread across various global locations, leads to extended lead times, elevated transportation costs, and production delays—ultimately impacting the end consumer.

Through the “Electric Vehicle Supply Chain” section, my objective is to provide expert insights into the challenges and opportunities inherent in the EV supply chain. I aim to offer actionable strategies for professionals in the industry to optimize supply chain operations, enhance inventory management, reduce costs, and integrate sustainability.

The research and articles featured in this section will explore how the EV supply chain can evolve to meet growing consumer demands while adapting to the rapidly changing global market dynamics.

With years of firsthand experience in the electric vehicle industry, I’ve encountered the complexities and inefficiencies of the EV supply chain. To deepen my understanding of supply chain optimization, I’ve enrolled in the MITx MicroMasters® Program in Supply Chain Management. By combining industry experience with advanced academic knowledge, I aim to provide effective solutions to optimize the EV supply chain, improve operations, and continue offering educational content on the Electric Vehicle Geek blog to drive innovation and promote sustainable growth in eco-friendly mobility solutions.