In this guide, we are going to talk about electric vehicle battery geometry, the different types of electric vehicle battery geometries, the advantages and disadvantages of each battery geometry, and the future and challenges of using batteries in electric vehicles.

Whether you are researching what to look for in an electric vehicle battery before purchasing an electric vehicle, or a current electric vehicle owner looking to learn more about the geometry of their electric vehicle battery and how it affects their day-to-day lives, this guide is what you are looking for!

Table of Contents

Electric Vehicle Battery

Batteries are the mainstream electric vehicle energy storage system that most people are familiar with since modern electric vehicles sold today feature batteries as their main energy storage system such as Tesla which we are all familiar with as Americans.

Batteries have been a preferred energy storage system by electric vehicle manufacturers such as Tesla for their portability, and can convert stored chemical energy into electrical energy with high-efficiency thanks to their multiple electrochemical cells.

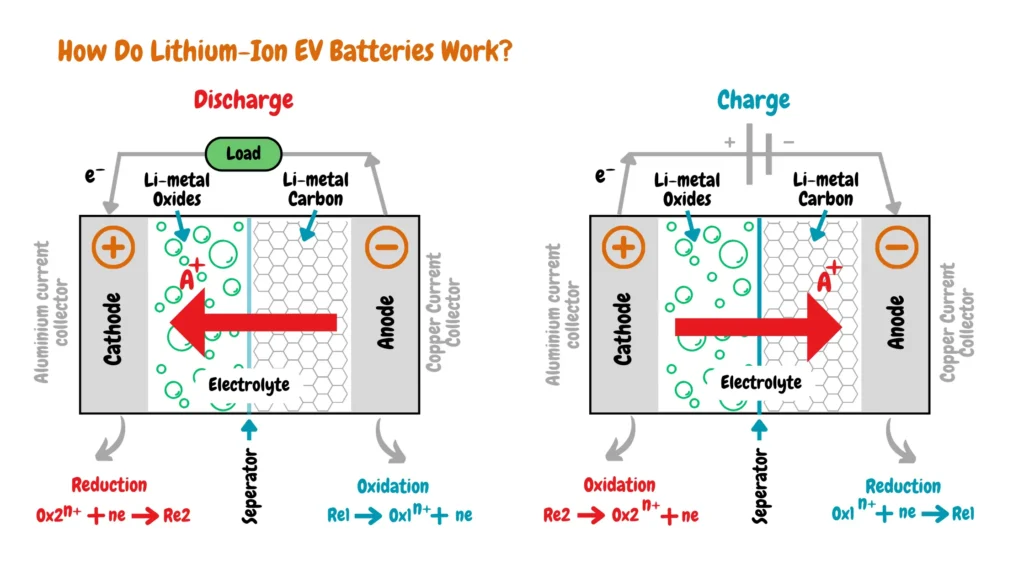

Batteries used in electric vehicles are rechargeable batteries, rechargeable batteries feature multiple electrochemical cells that allow the chemical reactions to take place inside the battery, without gas emissions during operation, and allow the ingress and removal of the reaction processes throughout the materials over cycles.

All types of batteries used in electric vehicles feature an electrode, an anode, and a cathode as shown in the image below:

Types of Electric Vehicle Battery Geometry.

Several types of electric vehicle batteries have been used in the manufacturing of electric vehicles, however, the most common type of battery is the Lithium-ion battery which currently dominates the market and it comes with most modern electric vehicles such as Tesla.

I first came to get hands-on experience with an electric vehicle lithium-ion battery when I bought my Jeep 4xe, being an electric vehicle geek, I attended various events and functions that talked about electric vehicle battery fires where I learned that there are various types of lithium-ion batteries in electric vehicles which come in different geometries small and large cylindrical, prismatic and pouch.

I learned how the geometry of the electric vehicle battery is crucial in thermal management, durability of the battery, and even real-world applications.

Cylindrical Cells Electric Vehicle Battery

We analyzed electric vehicle battery fires reported in various parts of the country at random and concluded that few vehicles with lithium-ion batteries that feature cylindrical cells were common and less susceptible to electric vehicle battery fires for they are able to retain their shapes inside their enclosures.

Electric vehicles with lithium-ion batteries that feature cylindrical cells can last long and structurally can withstand abuse such as shock and vibrations that modern off-road electric vehicles experience in the real world, so if you are looking for an electric vehicle with a structurally durable battery that can withstand the shocks and vibrations we recommend considering an electric vehicle with batteries made of cylindrical cells.

Before rushing to get yourself an electric vehicle with a lithium-ion battery that features cylindrical battery cells, our research also showed that this battery was also poor in heat transfer rates as the battery size increased.

Prismatic Cells Electric Vehicle Battery.

Electric vehicles with prismatic cell batteries on the other hand have better heat transfer rates and more efficient with increased size and are less susceptible to electric vehicle battery fires due to thermal management issues compared to electric vehicles with cylindrical cells especially when a bigger battery is involved.

Prismatic cells electric vehicle batteries are usually enclosed in semi-hard plastic covers and due to their features they are most suitable for assembly in electric vehicles, battery swaps, and replacements. So if you are looking for an electric vehicle with a bigger battery that is efficient, has better thermal management, and is easy to replace we recommend an electric vehicle battery with prismatic cells.

Pouch Cells Electric Vehicle Battery

Pouch electric vehicle batteries on the other hand have high energy/power densities compared to cylindrical and prismatic cell batteries without the extra packaging. The reason why pouch cell batteries and prismatic cell batteries are not common is that they require retaining plates that make them less durable, and susceptible to damage or even electric vehicle battery fires over time due to exposure to shock and vibration unless additional precautions are taken which would in turn increase the costs of the batteries, increase the size of the battery and also its weight which would affect the electric vehicles dynamics.

The Future of Electric Vehicle Batteries

As per what we are observing in the electric vehicle manufacturing industry, there is high demand for electric vehicle batteries that have a high discharge power, good recharging capabilities using home EV chargers, cycling capabilities, and high battery capacity as consumers have range anxiety especially potential electric vehicle buyers converting from internal combustion engine vehicles (ICEV).

Why do Electric Vehicle Manufacturers Prefer Batteries?

Batteries are the most used electric vehicle energy storage system used in all electric vehicles and hybrid electric vehicles due to their efficiencies compared to other energy storage systems such as ultra-capacitors, electric vehicle batteries are also able to deliver peak and average power without compromising on their efficiencies.

We do believe that the reason why batteries are here for the foreseeable future compared to other electric vehicle battery management systems is their battery characteristics, one of the notable characteristics is the battery capacity measured in AH, the energy stored on the battery measured in kWh, as well as the power measured in kW. Using this key battery characteristic that is usually displayed in your electric vehicle infotainment system when charging your battery or using your electric vehicle we can get to understand how fast the battery is depleted, and the state of charge (SOC) which is the percentage of charge available in the electric vehicle battery.

To get the most accurate readings and diagnostics of our EV battery, we use the Autel MaxiSys Ultra EV.

Autel MaxiSys Ultra EV Review

This advanced tool provides detailed battery analysis, allowing us to monitor capacity, energy, and power levels effortlessly. With real-time data and in-depth diagnostics, it ensures optimal battery performance and helps extend the lifespan of your EV.

The Autel MaxiSys Ultra EV offers unparalleled control and precision over battery management, making it an essential tool for any EV owner. Whether you’re a professional technician or an EV enthusiast, this tool empowers you to keep your vehicle running smoothly.

Challenges of Batteries in Electric Vehicle Manufacturing & Adoption.

The use of batteries in electric vehicles faces a challenge, and that is batteries have a low specific energy, density, and refueling charging rates compared to using fossil fuels to power vehicles. Their low specific energy, density, and refueling charging rates limit electric vehicle range, increase their sizes affect the electric vehicle dynamics, and also their costs which makes electric vehicles with batteries expensive due to high battery costs.

The high costs associated with optimizing the battery are later transferred to the consumer with a high price tag for electric vehicles, which in turn prevents widespread adoption of electric vehicles.

James Ndungu is a certified EV charger installer with over five years of experience in EVSE selection, permitting, and installation. He holds advanced credentials, including certification from the Electric Vehicle Infrastructure Training Program (EVITP) and specialized training in EV charging equipment and installation, as well as diplomas in EV Technology and Engineering Fundamentals of EVs. Since 2021, James has tested dozens of EV chargers and accessories, sharing expert insights into the latest EV charging technologies.