Junction boxes are essential in electric vehicle branch circuits for EV charger installations, providing crucial protection for EV charger installation feeder cable connections and splices. They shield these connections from dust, moisture, and other potential hazards, ensuring reliable power distribution to subpanels and EV chargers.

Electric vehicle branch circuits can be complex, and one crucial electrical component that goes unnoticed but plays a significant role in ensuring safety and functionality are electrical junction boxes commonly used when installing hardwired EV chargers, integrating renewable EV charging systems circuits, or organizing and managing electric vehicle branch circuit conduits and fittings, making maintenance and repairs of electrical vehicle branch circuit more accessible.

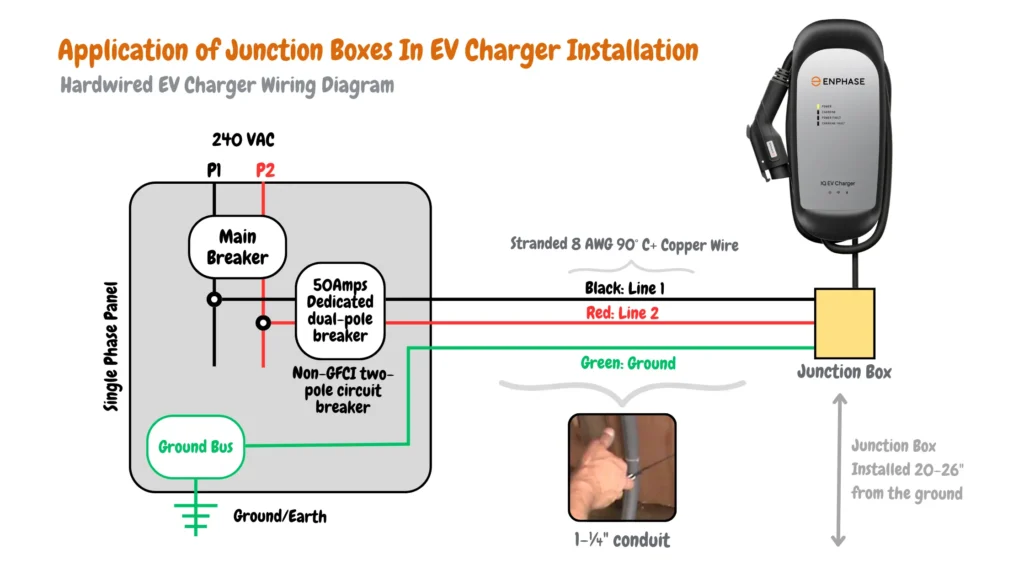

The diagram below shows how we used a junction box to enclose our hardwired EV charger wire connection with 50-amp feeder cables running from a 50-amp dedicated circuit breaker housed in an electrical panel.

Junction boxes used in EV charger installations come in various sizes, shapes, and designs to accommodate different types of electric vehicle branch circuit devices and wiring configurations, they are typically installed in walls, ceilings, or floors to provide safe and secure housing for extending EV charger feeder cables.

Junction boxes are commonly used in indoor and outdoor single-home EV charger installations, multiple EV charger installations, and commercial EV charger installations.

Table of Contents

At a Glance: Our Top Picks

Best Junction Boxes for EV Charger Installation

Depending on the functions of your junction box in EV charger installations, we have outlined some of the junction boxes we use and recommend depending on the type, we have categorized the junction boxes depending on the type, in our list you will find plastic, metal, weatherproof and underground junction boxes that we use and recommend for residential and commercial EV charger installations.

LeMotech Junction Box

Ideal for most indoor locations, offering a cost-effective solution.

MAKERELE Junction Box (Outdoor & Indoor)

Ideal for most indoor locations, offering a cost-effective solution. Protects against moisture and extreme temperatures, perfect for outdoor installations.

BUD Industries Metal Junction Box

Well-suited for grounded metallic conduit systems and areas requiring additional durability.

LemonBest Underground Junction Box

Engineered for subterranean installation, these junction boxes are purpose-built to ensure safe burial underground, catering specifically to the stringent requirements of EV charger configurations.

Criteria for Selecting Junction Boxes in EV Charger Installations

Our criteria for selecting junction boxes for EV charger installations are based on practical expertise and experience in the field. We prioritize junction boxes with robust construction capable of withstanding environmental conditions and ensuring long-term reliability. These boxes can be used for various applications, including industrial, commercial, and residential EV charger installations, and they adhere to detailed specifications for enclosure materials, construction methods, finishes, and performance ratings.

Furthermore, we prioritize junction boxes that support efficient wiring practices and offer sufficient protection against moisture, dust, and other external elements. Our selection process focuses on products that meet rigorous durability and safety standards critical for EV charger installations.

These junction boxes adhere to safety guidelines and electrical codes for all types of installations. They ensure compliance with clearance requirements, grounding practices, and protective measures, demonstrating our commitment to providing reliable and compliant solutions.

Types of Junction Boxes Used in EV Charger Installations

While there are a variety of junction boxes for EV charger installation to choose from, it’s most important to use a junction box for its intended use in an electrical vehicle branch circuit.

Plastic Junction Boxes

For example, you can choose plastic junction boxes for residential home EV charger installation of hardwired EV charger connections with feeder cables from electrical panels that should enclose the wire connection and prevent them from being exposed to external elements and from being exposed to reduce the risk of electrical shocks and fires.

Weatherproof Junction Boxes

Weatherproof junction boxes used for outdoor EV charger installations should be designed to withstand exposure to the elements, to ensure your electrical vehicle branch circuits and wire connections remain secure even in challenging conditions.

Metal Junction Boxes

Metal junction boxes are frequently utilized in EV charger installations due to their durability, especially in outdoor and commercial settings where they can withstand potential impacts.

Metal junction boxes used in EV charger installations should be constructed using corrosion-resistant metals such as steel or aluminum, you should also inspect the metal thickness to ensure that it can support the electric vehicle branch circuit wiring and any other EV charging devices you want to install inside the metal junction box (NEC 314.28).

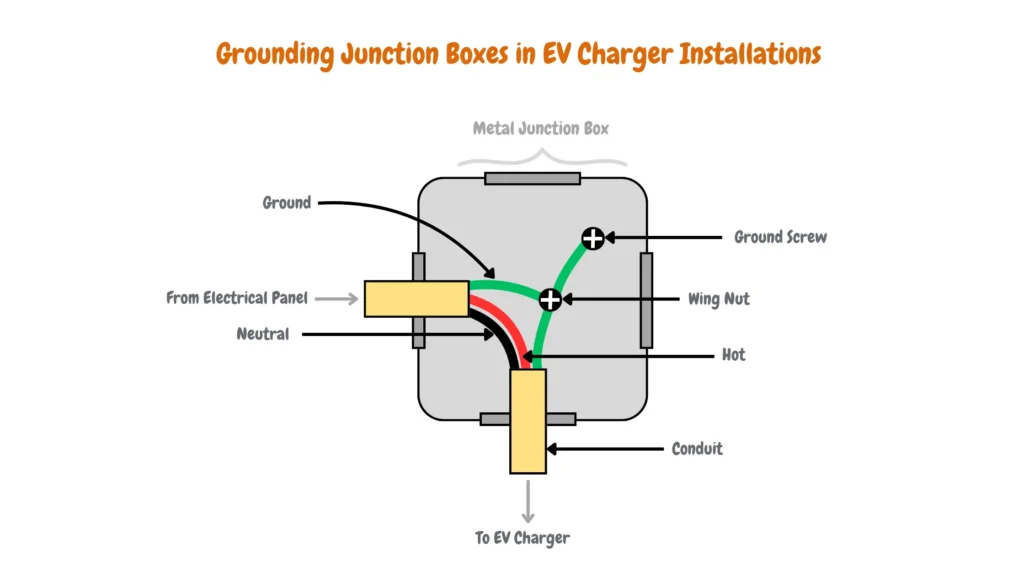

It is crucial to ensure effective grounding when installing a metal junction box in an EV charger branch circuit (NEC 250.110). This involves connecting the grounding conductor securely to a designated grounding screw or employing an approved alternative grounding method. The grounding screw must be installed in a threaded or factory-prepared hole to maintain electrical integrity and safety standards as shown in the illustrative image below:

Underground Junction Boxes

For EV charging stations installed outdoors such as in parking lots, you can opt for underground junction boxes that protect underground electric vehicle branch circuit wire connections and splices in outdoor landscapes.

Installing Junction Boxes in EV Charger Circuits

Proper installation of junction boxes for electric vehicle branch circuits is crucial to ensure they effectively enclose wire connections and splices and protect them from external elements like dust, moisture, and physical damage to reduce the risk of electrical shocks and fires.

Always adhere to the National Electrical Code (NEC) and any local electrical codes when working with the electric vehicle branch circuit wiring. This ensures safe and compliant installations.

Before installing junction boxes, it’s essential to plan and design your wiring configurations and placements, the effects of wire connections and splices involve considering their impact on safety, performance, durability, compliance, and overall electric vehicle branch circuit integrity.

Install junction boxes strategically at points requiring electrical connections, ensuring easy accessibility for maintenance. For instance, junction boxes for hardwired EV chargers and feeder wires should be positioned between 20 to 26 inches from the ground, optimizing cable length and charger placement.

Ensure junction boxes are installed in accessible locations; avoid placing them in concealed wall or ceiling spaces that hinder future access. Additionally, always use solid covers without holes to enclose junction boxes.

Properly sealing junction boxes is crucial to prevent moisture, dust, and other external elements from infiltrating and potentially causing shorts or corrosion in the wire connections and splices of an electric vehicle branch circuit. This helps maintain the integrity and longevity of the cables used in the circuit.

A Guide to Electric Vehicle Branch Circuit Junction Box Wiring

Always follow the specific recommendations provided by the EV charger manufacturer, and wire connector manufacturer for optimal performance and safety.

Utilize appropriate wire connectors (e.g., wire nuts, crimp connectors) for secure and reliable connections, this can be dependent on the terminal types of wires from the EV chargers, and manufacturers’ recommended connection methods.

Strip electric vehicle branch circuit wire ends to the recommended length based on the connector type. Leave enough slack within the box for future maintenance or adjustments.

The National Electrical Code (NEC) acts as the electrical safety bible in the US. It recognizes the critical role of color coding in preventing electrical hazards by securing joining wires of the same type. Maintain the original wire color coding throughout the box for easier identification during troubleshooting.

| Function (Lable) | Main Color | Alternative Color |

|---|---|---|

| Single Phase Line (L) | Black | Red (2nd Hot) |

| Three Phase Line (L1) | Black | Brown |

| Three Phase Line (L2) | Red | Orange |

| Three Phase Line (L3) | Blue | Yellow |

| Neutral (N) | White | Grey |

| Protective Earth or Ground (PG) | Green, Green – Yellow or Bare Conductor |

Select a junction box that can accommodate the electrical vehicle branch circuit wires, connections, and splices without overcrowding. Limit the number of splices for enhanced reliability. Use approved methods such as heat shrink connectors or in-line splices if needed. Ensure the total wire volume within the box adheres to the manufacturer’s fill capacity rating to mitigate overheating and reduce fire risks.

Editors’s Notes

We have used different brands and types of junction boxes more than we can remember, some we purchased by the client and some we purchased in electronics shops depending on their availability, however, some electronic junction boxes have stood out and we tend to use them more, due to ease of installation, functionality, and aesthetics of installations work.

Junction boxes that have stood out due to first-hand installation experiences include; LeMotech Junction Box, MAKERELE Junction Box (Outdoor & Indoor), BUD Industries Metal Junction Box, and LemonBest Underground Junction Box. Depending on your intended function of a junction box in an electric vehicle branch circuit, with the listed junction boxes we are sure you will find one or two junction boxes for your complete simple or complex residential or commercial EV charger installations.

James Ndungu is a certified EV charger installer with over five years of experience in EVSE selection, permitting, and installation. He holds advanced credentials, including certification from the Electric Vehicle Infrastructure Training Program (EVITP) and specialized training in EV charging equipment and installation, as well as diplomas in EV Technology and Engineering Fundamentals of EVs. Since 2021, James has tested dozens of EV chargers and accessories, sharing expert insights into the latest EV charging technologies.

Last update on 2026-03-07 / Affiliate links / Images from Amazon Product Advertising API